© 2025 Messer Cutting Systems, Inc.

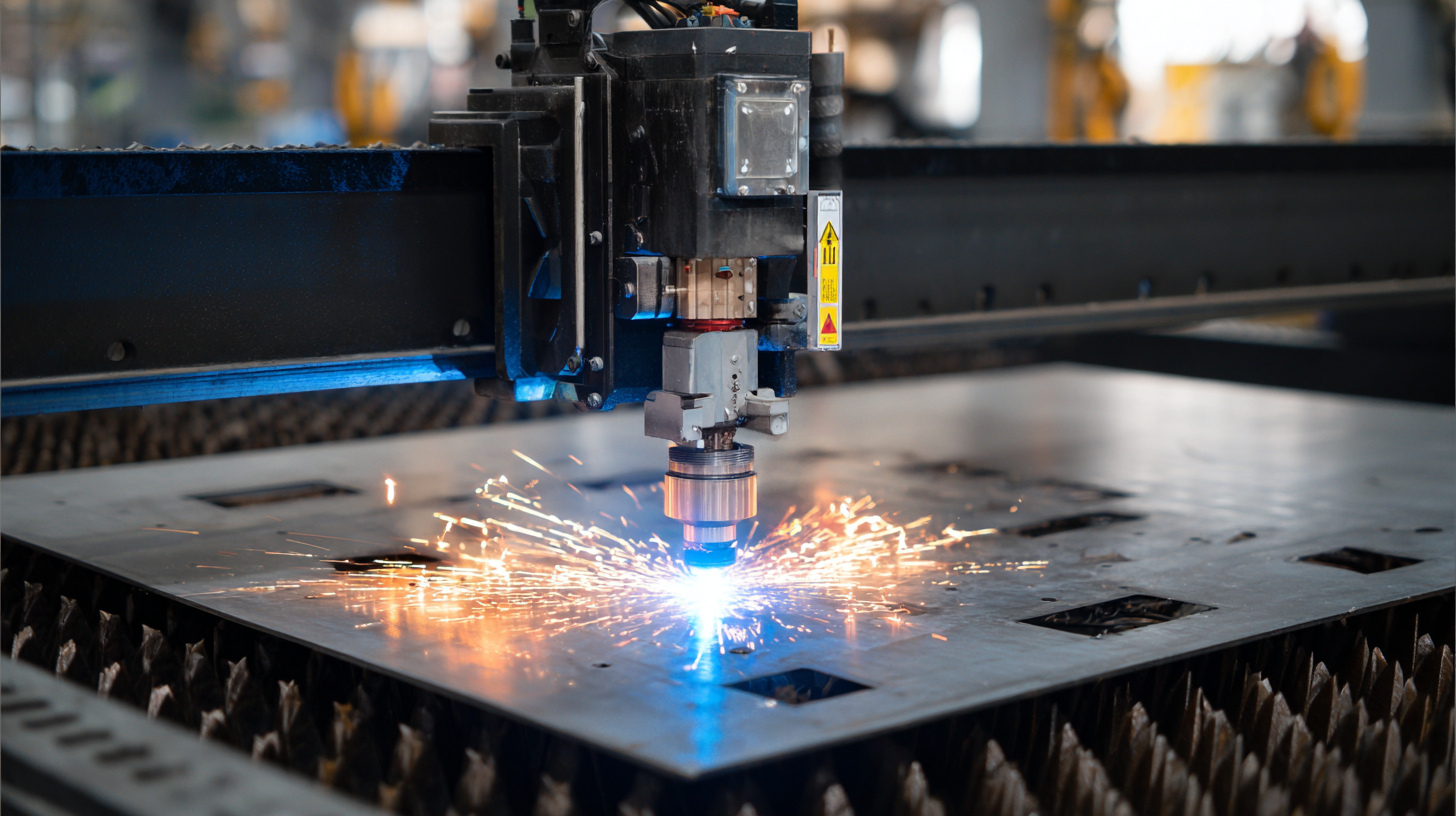

In today's fast-paced manufacturing environment, choosing the right equipment is crucial for staying competitive and ensuring operational efficiency. One of the most transformative tools in the fabrication industry is the CNC plasma cutting machine, which combines precision and speed to produce high-quality cuts in various materials.

Understanding the benefits of selecting the best CNC plasma cutting machine tailored to your business needs can significantly enhance your production capabilities. From increased productivity and reduced labor costs to enhanced material utilization and superior cut quality, the right CNC plasma cutting machine can make a significant difference in your operations.

This guide will delve into the essential factors to consider when investing in a CNC plasma cutting machine and how to align your choice with your business goals to achieve optimal outcomes.

Selecting the right CNC plasma cutting machine for your business is a critical decision that can significantly impact your operational efficiency and quality of output. One essential factor to consider is the cutting thickness capability of the machine. According to a recent industry report from MarketsandMarkets, the global CNC plasma cutting market is projected to grow at a CAGR of 4.5% from 2023 to 2028, largely driven by advancements in cutting technologies that allow for greater flexibility in thickness handling. Understanding the range of materials you will be cutting and the required thickness can guide you towards a model that fits your needs, particularly if you work with stainless steel or aluminum, which require specific machine settings.

Another critical consideration is the software compatibility and ease of use. An advanced CNC plasma cutter often comes with sophisticated software that allows for intricate designs and automation. Research by IBISWorld indicates that 60% of business owners prioritize ease of use and software accessibility when selecting machinery, as this directly affects training costs and time to proficiency. Investing in a machine with intuitive software not only streamlines the operational process but also enhances productivity, allowing your team to focus on craftsmanship rather than troubleshooting.

When selecting the best CNC plasma cutting machine for your business needs, it's essential to focus on features that enhance efficiency. Recent market analysis indicates that the CNC plasma cutting machine segment is projected to grow significantly, driven by increased demand in various applications, especially in the metal cutting industry. The integration of high-efficiency servomotors and lightweight rigid structures in plasma cutting systems is crucial. These advancements not only improve cutting speeds but also reduce overall operational costs—attributes that are highly sought after in a competitive market.

Further highlighting the industry's focus on productivity, innovations such as real-time adaptive height control and advanced software integration are transforming CNC plasma cutting machines. Reports indicate that these technologies can significantly increase throughput and accuracy, offering businesses a competitive edge. As companies look to optimize their cutting processes, considering machines with the latest technological features becomes imperative. With the plasma cutting machine market projected to reach new heights, investing in equipment that boasts cutting-edge features will be key to maintaining efficiency and meeting growing demands.

When selecting a CNC plasma cutting machine, understanding the different types available is crucial for aligning them with your business needs. CNC plasma cutters can mainly be classified into three categories: low-power, medium-power, and high-power systems. Low-power machines are ideal for lighter materials and small businesses aiming for precision in intricate designs. Medium-power machines can handle thicker materials and are suitable for a range of industrial applications. High-power systems, on the other hand, excel in cutting heavy-duty materials, making them perfect for large-scale manufacturing operations.

Tip: When deciding on the power level, consider the thickness and type of material you plan to cut. This will not only enhance efficiency but also save costs in the long run.

Another aspect to consider is the type of CNC controller your machine will use. Some machines offer advanced features such as motion control and real-time adjustments, while others may be simpler and more user-friendly. Choosing a machine with a controller that suits your team's skill level can significantly impact productivity.

Tip: Investing in training for your staff can maximize the benefits of a more complex system, turning your CNC plasma cutter into a powerful asset for your business.

Investing in a CNC plasma cutting machine can significantly enhance your business's operational efficiency and precision. One of the key advantages is the machine's ability to deliver clean, accurate cuts in various materials, including steel, aluminum, and copper. This not only reduces waste but also minimizes the time required for post-processing. With faster setup times and higher cutting speeds compared to traditional methods, CNC plasma cutting can lead to increased productivity and profitability.

When selecting the right machine, consider factors such as the size of the material you'll be working with and the thickness of the cuts required. Tips for choosing the best CNC plasma cutting machine include evaluating the cutting speed and technology used, as well as the software compatibility for design and operation. Look for machines that offer easy-to-use interfaces and robust support systems, enabling your team to adapt quickly and utilize the machine's full potential.

Furthermore, investing in a CNC plasma cutter is not just about the immediate benefits. It can position your business as a leader in your industry by offering high-quality fabrication services. Consider the long-term return on investment and potential for expansions, such as additional features or upgrades that align with your evolving business needs.

| Feature | Description | Benefits |

|---|---|---|

| Cutting Speed | Typically ranges from 10 to 25 inches per minute. | Increased productivity and efficiency in operations. |

| Material Thickness | Can cut materials up to 1 inch thick. | Versatility in handling different project requirements. |

| Control System | Uses advanced CNC software for precise cutting. | Enhanced accuracy and reduced material waste. |

| Portability | Some models are designed to be easily moved between job sites. | Greater flexibility for on-site cutting tasks. |

| Power Requirements | Generally requires standard electrical outlets, but options are available for high-power needs. | Compatibility with various power sources for diverse operational environments. |

| Maintenance | Regular check-ups and minimal downtime needed. | Long-term cost-effectiveness and reliability. |

CNC plasma cutting has become a pivotal technology for various industries, yet misconceptions about its efficiency and safety persist. A common myth is that plasma cutting is less precise compared to laser cutting. However, recent advancements in CNC plasma technology have significantly improved its precision. Farmers, in particular, are turning to ultra-accurate CNC plasma cutters due to their superior performance in sheet metal applications, which is essential for a range of agricultural equipment. The CNC plasma cutting machines market is expected to grow substantially, reaching approximately USD 673.2 million by 2024, highlighting the increasing adoption of this technology in manufacturing processes.

Another misconception involves the safety of plasma cutting equipment. Incidents, such as injuries reported among inexperienced operators, cannot be overlooked; however, proper training and safety measures can drastically reduce risks. The industry is developing solutions like advanced cleaning machines that help maintain equipment efficiency by removing slag buildup on cutting tables, thus preventing potential hazards related to mishandling. These innovations are not only enhancing the operational safety of plasma cutting processes but also improving productivity, making them a valuable asset for businesses looking to modernize their fabrication capabilities.

© 2025 Messer Cutting Systems, Inc.