© 2025 Messer Cutting Systems, Inc.

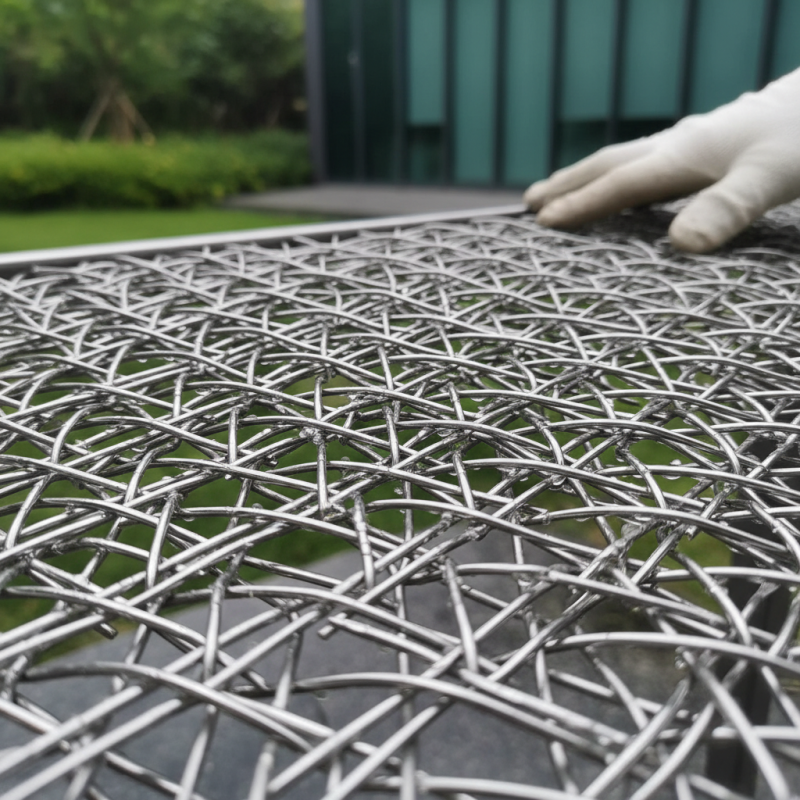

stainless steel woven wire mesh is a remarkable material with numerous benefits. Commonly used in various industries, it offers versatility and durability.

One key advantage is its resistance to corrosion. This makes it suitable for outdoor applications, such as in gardens or construction sites. The aesthetic appeal of stainless steel woven wire mesh also stands out. Its shiny surface and intricate patterns can enhance visual designs.

Moreover, this mesh is easy to clean and maintain. Regular cleaning keeps it looking new, preserving its integrity. However, there are some concerns to consider. Selecting the right size and type can be challenging. The cost may also be a factor for some users. By weighing these benefits against potential drawbacks, one can appreciate the true value of stainless steel woven wire mesh.

Stainless steel woven wire mesh stands out for its exceptional corrosion resistance. This property makes it ideal for various applications, including construction and food processing. Unlike other materials, stainless steel does not rust or degrade when exposed to moisture. This durability means lower replacement costs and less maintenance over time.

In harsh environments, like coastal areas, using stainless steel becomes crucial. Its ability to withstand saltwater corrosion protects structures and equipment. However, not all stainless steel types offer the same level of resistance. It’s essential to choose the right grade based on the specific conditions. Some users mistakenly assume all stainless steel is equal.

Additionally, the aesthetics of stainless steel should not be overlooked. Its shiny surface adds a modern touch to projects. Yet, it requires periodic cleaning to maintain that look. Realizing that it might not be completely resistive to staining highlights the need for care. Understanding these factors provides a more comprehensive view of its advantages.

Stainless steel woven wire mesh has diverse applications across various industries. In construction, it provides structural support and safety. It is crucial for reinforcing walls and ceilings. The mesh enhances stability while allowing for airflow and light penetration. This is important in areas needing both strength and visibility.

In the food industry, the mesh offers hygienic solutions. It is used in conveyor belts and strainers. This ensures safe handling of food products. However, given its exposure to residues, regular cleaning is necessary. Neglecting maintenance could lead to contamination issues.

Tips: Consider the specific environment when choosing mesh types. Different grades of stainless steel are available. Ensure it matches your operational needs. Regular inspections can help maintain safety and efficiency. Always think ahead to prevent future issues.

| Benefits | Description | Applications |

|---|---|---|

| Corrosion Resistance | Stainless steel is highly resistant to rust and corrosion, making it ideal for harsh environments. | Food processing, marine applications |

| Durability | Offers great longevity and withstands extreme conditions without degradation. | Construction, industrial applications |

| Aesthetic Appeal | The sleek and modern appearance enhances designs in architecture and art. | Interior décor, architectural features |

| Low Maintenance | Requires minimal upkeep compared to other materials, saving labor and maintenance costs. | Public infrastructure, industrial facilities |

| Versatility | Can be used in various forms and designs, suited to numerous applications. | Automotive, aerospace, medical devices |

| Temperature Resistance | Withstands high temperatures without deforming or losing strength. | Ovens, heat exchangers |

| Recyclability | 100% recyclable, reducing environmental impact and promoting sustainability. | Waste management, eco-friendly projects |

| Safety | Non-reactive and safe for food handling, ensuring hygiene standards. | Food processing, medical industries |

| Filtration | Ideal for separating particles from liquids or gases due to its fine mesh forms. | Water treatment, air filtration |

| Strength | High tensile strength provides excellent support in structural applications. | Bridges, heavy machinery |

Stainless steel woven wire mesh stands out for its exceptional durability and longevity. Unlike other materials, stainless steel resists corrosion and rust. This resistance ensures a longer lifespan, even in harsh environments. For instance, it works well in food processing and chemical industries. These settings often involve exposure to moisture and chemicals, yet stainless steel remains unaffected.

Moreover, the mesh can endure extreme temperatures. It maintains structural integrity, whether in frigid winters or intense heat. This versatility makes it suitable for various applications, including filtration and construction. However, not all stainless steel wire meshes are created equal. Factors like weaving technique and wire gauge play a role in performance. Choosing the correct specifications is crucial for optimal results.

Occasionally, people overlook the maintenance aspect. While stainless steel is low-maintenance, it still requires periodic cleaning to avoid buildup. Neglecting this can lead to a decline in appearance and performance. Understanding these nuances is vital for maximizing the durability of woven wire mesh products. A little care goes a long way in ensuring its longevity.

Stainless steel woven wire mesh is a popular choice for various applications. One of its standout features is its easy maintenance and cleaning. The smooth surface of stainless steel prevents dirt and grime from building up. This means less time spent on cleaning tasks.

When it comes to cleaning, a simple wipe with a damp cloth often suffices. For tougher stains, a mild detergent can be used. Avoid harsh chemicals, as they may damage the finish. Regular maintenance can prolong the life of the mesh. However, be mindful of areas that may accumulate debris. Sometimes, overlooked corners can gather dirt over time.

Tips for maintaining your stainless steel mesh: Check for any signs of rust, even if it's rare. A little preventive care goes a long way. Consider using a soft brush for deeper cleaning. Additionally, inspect the mesh periodically for any wear and tear. This attention to detail can help ensure a longer lifespan for your woven wire mesh.

Stainless steel woven wire mesh offers significant cost-effectiveness over time. Its durability means fewer replacements are necessary, saving money in the long run. Many industries use this material for filtration, reinforcing, and support. When other materials fail, stainless steel stands strong. This longevity provides a clear financial advantage.

Installation costs can be higher upfront. However, the maintenance required is minimal. Unlike alternatives, it resists rust and corrosion. This resistance means less frequent repairs and replacements. Many users find that the initial investment pays off. Over the years, savings accumulate, reflecting its true value.

Some people may overlook its benefits due to higher initial costs. They often opt for cheaper options. Yet, these alternatives may lead to higher long-term expenses. This choice shows a short-sighted approach. Stainless steel woven wire mesh remains an ideal investment for those who value quality and longevity. Embracing this material requires understanding its true benefits.

© 2025 Messer Cutting Systems, Inc.