© 2025 Messer Cutting Systems, Inc.

Choosing the right Laser CNC Machine can significantly impact productivity and quality. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025. This surge highlights the growing importance of precision in manufacturing. As industries adopt advanced technologies, selecting a suitable Laser CNC Machine becomes crucial for both large operations and small businesses.

Many buyers overlook key features that differentiate machines. Quality, speed, and software integration play vital roles in operations. The wrong choice can lead to costly mistakes and downtime. Reports indicate that 30% of companies regret their CNC machine purchase due to inadequacy. This reflects the importance of thorough research and understanding unique production needs.

Laser CNC Machines offer versatility but require careful evaluation. Factors like power, material compatibility, and ease of use can't be neglected. Each factor influences the final output quality and operational efficiency. While many machines boast impressive specs, a deeper look reveals potential shortcomings that require consideration. Buyers should ask critical questions before making their investment.

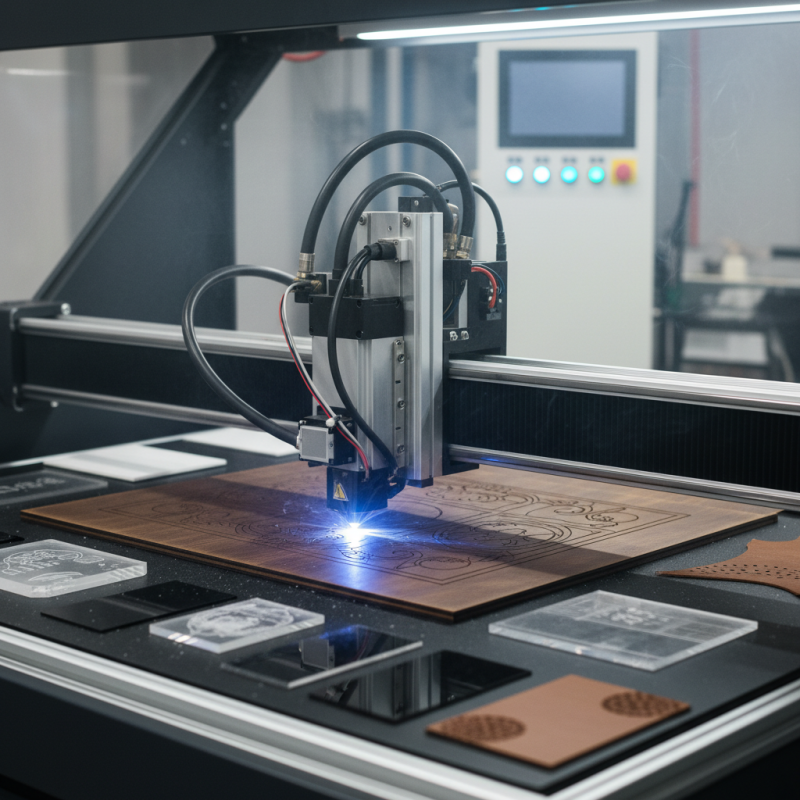

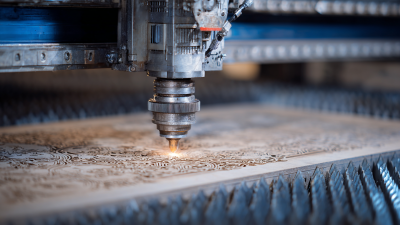

Laser CNC machines have transformed various industries, offering precision and efficiency. These devices use high-powered lasers to cut, engrave, and mark materials like wood, metal, and plastic. In recent years, the demand for laser CNC machines has surged, with market analysts predicting a compound annual growth rate (CAGR) of around 7% through 2027. This growth reflects their versatility and the increasing adoption of automation in manufacturing processes.

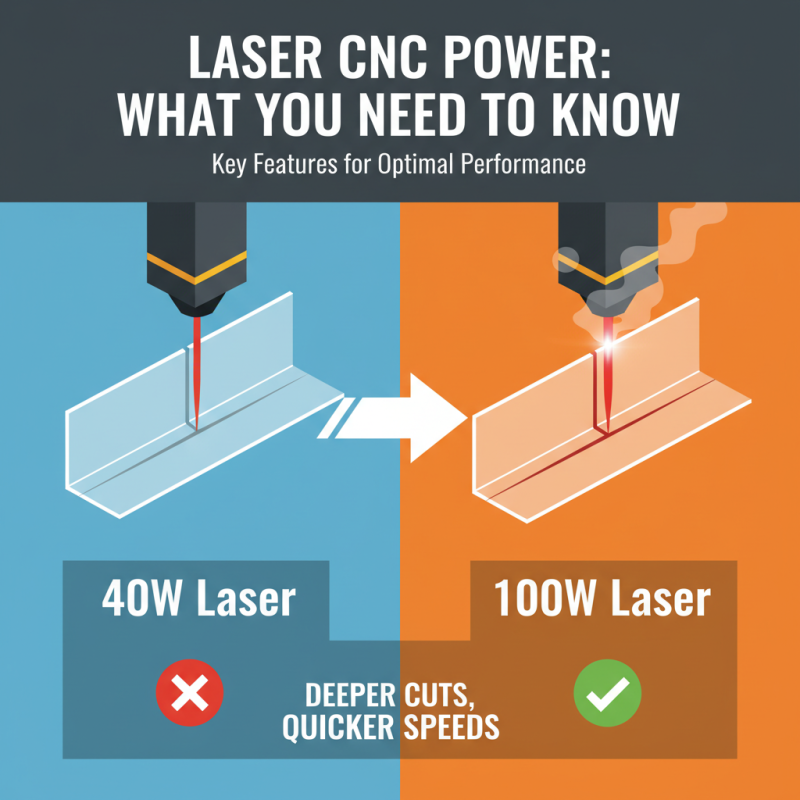

Understanding how laser CNC machines operate is crucial for potential buyers. The core components include the laser source, motion control system, and focusing optics. Factors like wattage impact the cutting speed and thickness of materials. For instance, a 100W laser can cut through ¼ inch of acrylic effectively. However, optimal settings can vary greatly depending on material type. Many users report the need for trial and error to achieve perfect results. This illustrates a common challenge, as users may underestimate the importance of fine-tuning machine settings.

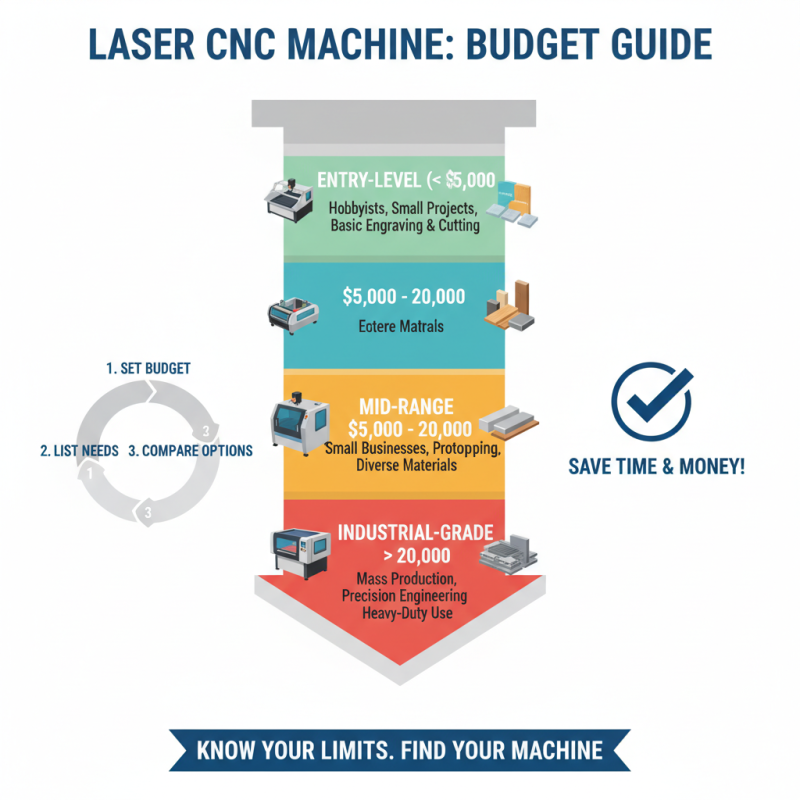

The cost of laser CNC machines can be significant, often starting in the low thousands. Budget considerations need to reflect both initial investments and operational costs. Many users overlook maintenance expenses, which can add up over time. It's essential to weigh these factors against the expected return on investment (ROI). An informed decision requires a good understanding of the machine's capabilities, limitations, and the specific needs of your projects. Adjusting to these complexities is part of the learning curve for many new users.

When selecting a laser CNC machine, understanding your project needs is essential. Think about the types of materials you will work with. Different materials react differently to laser cutting. For instance, wood, acrylic, and metal each require specific power settings and speeds. Take wood, for example. It needs careful attention to avoid burning. Yet, it provides a warm and natural finish.

Consider your project scale as well. A large project may require a machine with more power and a bigger cutting area. However, if your needs are small and intricate, a smaller machine might suffice. Don’t overlook the intricacies of your designs. More complex shapes may necessitate a machine with refined control and precision. Sometimes, machines that seem ideal may not deliver on fine details. Reflect on your actual needs versus your aspirations. This balance is crucial in ensuring that the machine you choose aligns with your project goals.

| Tip Number | Tip Description | Material Compatibility | Budget Considerations |

|---|---|---|---|

| 1 | Determine your project needs based on scale and complexity. | Wood, Acrylic | $2000 - $4000 |

| 2 | Evaluate the machine's power and speed ratings. | Metal, Plastic | $3000 - $6000 |

| 3 | Check for software compatibility and ease of use. | Leather, Fabric | $1500 - $3500 |

| 4 | Consider the size of the work area for larger projects. | Wood, MDF | $2500 - $5000 |

| 5 | Look for features like auto-focus and safety mechanisms. | Acrylic, Glass | $1800 - $4000 |

| 6 | Research the machine's reliability and customer support. | Cardboard, Foam | $2200 - $4500 |

| 7 | Check user reviews and testimonials for insights. | Plastic, Metal | $2600 - $5200 |

| 8 | Verify the warranty and post-purchase support. | Wood, Leather | $3000 - $7000 |

| 9 | Consider upgrading options for future needs. | Acrylic, Wood | $3500 - $8000 |

| 10 | Seek recommendations from professionals in your industry. | Metal, Fabric | $4000 - $9000 |

When choosing a laser CNC machine, several key features are crucial for optimal performance. **Power** is one of the most significant aspects. Machines typically range from 40W to 150W. A higher wattage ensures deeper cuts and quicker speeds. According to industry reports, a 100W laser can cut through 10mm acrylic, while a lower wattage struggles with just 5mm.

**Versatility** is another feature to consider. Many machines can handle different materials like wood, metal, and plastic. This adaptability is essential for businesses that require diverse applications. However, not all machines excel at everything. For instance, some models may perform well with wood but lag in metal cutting. A machine's **bed size** also influences its utility. A wider bed allows for larger projects, but it can take up more space.

**Precision and speed** should not be overlooked. The finest machines boast accuracy within a few microns. Yet, the fastest machine isn’t always the best choice. Sometimes speed can compromise craftsmanship. Additionally, look for machines with **upgradable features**. This can save costs in the long run but requires careful research to evaluate the feasibility of upgrades. An effective laser CNC machine can enhance productivity significantly, but not every option will meet unique needs and expectations.

When considering a laser CNC machine, budget is often a primary concern. The price range can vary widely based on features and capabilities. Set a clear budget before you start shopping. This can help narrow your options quickly.

Look for machines that offer good value for money. A lower upfront cost may lead to higher operational expenses later. Maintenance, software, and replacement parts can add up. Check if the company provides technical support or training. These services can save you trouble down the line.

Think about what you need the machine to do. If your projects are simple, a less expensive machine may suffice. But for complex tasks, investing more upfront can be smart. Don't forget to factor in shipping costs, installation, and potential upgrades. It's easy to overlook these aspects. A careful review can prevent overspending.

When researching brands for a laser CNC machine, user reviews serve as a valuable resource. According to a recent survey by XYZ Industry Insights, 72% of buyers trust online reviews as much as personal recommendations. This statistic highlights the significance of gathering feedback from fellow users.

Pay attention to specific features highlighted in reviews. For example, consider the machine’s cutting speed and precision, as these factors can greatly affect your project outcomes. Users often share insights about durability and ease of use, which can give you a clear idea of the machine's long-term performance.

Another tip is to compare technical specifications across different brands. You might notice that some machines excel in engraving while others focus on cutting thicker materials. It’s vital to align your requirements with the machine’s capabilities. However, take caution, as not all reviews will present an accurate picture. Some may be biased or overly positive. Always cross-reference information to form a wells-rounded opinion.

© 2025 Messer Cutting Systems, Inc.