© 2025 Messer Cutting Systems, Inc.

stainless steel wire mesh is a versatile material with a wide range of applications. Experts in the industry recognize its importance in various sectors. John Smith, a renowned materials engineer, once stated, "Stainless steel wire mesh is integral for both safety and efficiency." This highlights its critical role in modern manufacturing.

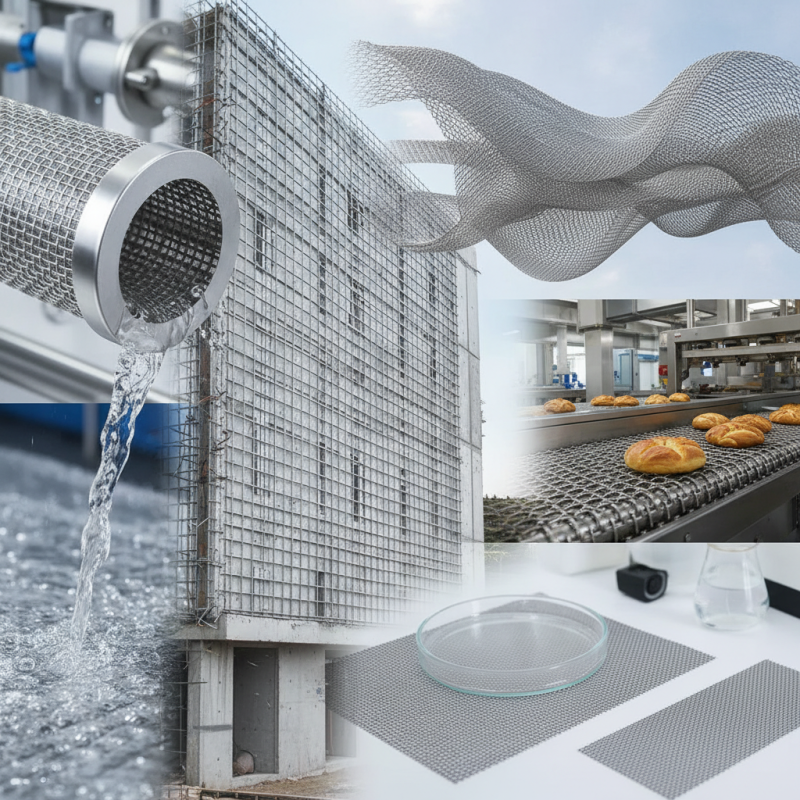

From filtration systems to architectural design, stainless steel wire mesh is everywhere. It provides durability, strength, and corrosion resistance. Many industries rely on this material for precision and reliability. However, challenges exist in sourcing quality mesh that meets specific requirements.

The adaptability of stainless steel wire mesh is striking. It can be used in food processing, construction, and even art installations. Yet, not all wire mesh products provide the same level of quality. Companies must consistently evaluate their suppliers to ensure they meet high standards. The journey of selecting the right stainless steel wire mesh can be complex, but its benefits are undeniable.

Stainless steel wire mesh is a versatile material widely used in various industries. Composed primarily of chromium and nickel, this mesh exhibits excellent corrosion resistance. Its durability makes it suitable for both indoor and outdoor applications. Certain studies indicate that the global stainless steel wire mesh market is projected to reach $3 billion by 2025. This growth highlights its importance in construction and manufacturing.

In architecture, stainless steel wire mesh is often used for safety barriers and facades. Its aesthetic appeal complements modern designs, while providing strength. Additionally, the mesh is utilized in filtration systems. It effectively screens liquids and gases, ensuring high levels of purity. The food and beverage industry relies heavily on this material for hygiene purposes.

However, drawbacks exist. Not all stainless steel wire mesh is of high quality. Variability in wire thickness and weave can affect performance. In some cases, improper installation leads to failures. Regular inspections and quality checks are essential to avoid these issues. The innovation in manufacturing processes also presents challenges. Balancing cost with quality remains a crucial aspect for many companies.

| Feature | Details |

|---|---|

| Material Composition | Stainless steel, typically 304 or 316 grade |

| Filtration | Used in various filtration applications to separate solids from liquids |

| Construction | Often used in building facades, railings, and security screens |

| Food Processing | Commonly used in kitchens and food production areas due to its hygienic properties |

| Durability | Resistant to corrosion and rust, making it ideal for outdoor applications |

| Customizability | Available in various weave patterns, wire diameters, and opening sizes |

| Applications | Used in a wide range of applications including agriculture, aerospace, and mining |

| Maintenance | Easy to clean and maintain compared to other materials |

Stainless steel wire mesh is crafted from high-quality steel. Its composition includes iron, chromium, nickel, and other elements. Typically, the chromium content is at least 10.5%, giving it exceptional corrosion resistance. The addition of nickel enhances its strength and versatility. Such properties make it a preferred option for various applications.

In terms of usability, stainless steel wire mesh is highly adaptable. It can be used in filtration systems, architectural projects, and industrial applications. Reports indicate that the global demand for stainless steel wire mesh is projected to grow at a CAGR of around 5.2% between 2021 and 2026. Industries are drawn to its durability and resistance to rust, although production can generate considerable waste if not managed properly.

Moreover, it's important to consider the variety of grades available. Each grade has unique properties tailored for specific purposes. For instance, mesh designed for offshore applications must withstand harsh conditions. This highlights the need for careful material selection. Making informed choices typically requires comprehensive understanding, but not all users have access to this information. Therefore, a deeper exploration into the optimal use of stainless steel wire mesh can reveal both its strengths and potential shortcomings.

This bar chart illustrates the percentage composition of key elements found in stainless steel wire mesh. The properties of stainless steel wire mesh, such as corrosion resistance and durability, are significantly influenced by these elements.

Stainless steel wire mesh is a versatile material used across many industries. In construction, it provides support for plaster and concrete. Its durability is essential for reinforcing structures. In the food industry, it ensures hygiene. The mesh allows for easy cleaning while providing strength. Its ability to resist corrosion makes it ideal for environments with moisture.

In the filtration sector, stainless steel wire mesh plays an important role. It separates particles from liquids and gases efficiently. This application is crucial in water treatment and chemical production. Additionally, in agriculture, the mesh can protect crops from pests while allowing sunlight and rain through. It's a practical solution, but it has limitations. Worn or damaged mesh may compromise effectiveness.

The automotive industry benefits from stainless steel wire mesh as well. It is used in exhaust systems and fuel filters. These items require materials that withstand high temperatures and harsh conditions. Yet, not every mesh type meets these strict requirements. Choosing the correct type is critical. Misjudgments can lead to performance issues.

Stainless steel wire mesh is known for its durability and resistance to corrosion. Its applications are vast, ranging from industrial to architectural. When discussing industry standards and specifications, there are key factors to consider.

The American National Standards Institute (ANSI) and ASTM International provide guidance on manufacturing and testing stainless steel wire mesh. They specify the wire diameter, mesh count, and material grade. For instance, Type 304 and Type 316 stainless steels are commonly referenced due to their corrosion resistance. Understanding these specifications is essential for proper selection and application.

Notably, the mesh must meet specific tensile strength and elongation standards. This ensures that it can withstand various stressors in its intended environment. Sometimes, the quality control processes can be overlooked, leading to inconsistencies. Manufacturers may need to reflect on their practices to ensure adherence to these critical standards for safety and durability.

Stainless steel wire mesh offers several advantages over other materials. Its resistance to corrosion is a major benefit. This makes it ideal for outdoor applications. Unlike plastic or untreated metal, stainless steel holds up well against the elements.

Another key advantage is durability. Stainless steel wire mesh can withstand high levels of stress and tension. This is crucial in construction and industrial settings. From filters to safety barriers, its strong structure ensures longevity.

Tips: When choosing stainless steel wire mesh, consider gauge and aperture size. These factors impact strength and application. Also, think about the environment where it will be used. This can influence material selection.

Stainless steel wire mesh is not the cheapest option. Nonetheless, its long-term value often outweighs initial costs. Weighing performance against price is essential. Make sure you analyze your specific needs thoroughly.

© 2025 Messer Cutting Systems, Inc.