© 2025 Messer Cutting Systems, Inc.

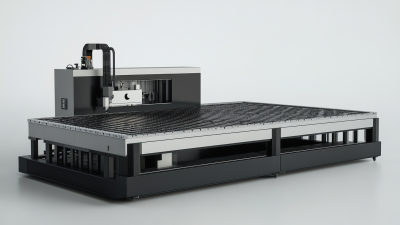

In recent years, the Cnc Laser Cutter has emerged as a transformative tool, revolutionizing both the artistic and industrial landscapes. This advanced technology not only enhances precision and efficiency but also opens up a realm of creative possibilities that were previously unimaginable. The intricate capabilities of Cnc Laser Cutters empower artists to push the boundaries of their craftsmanship, allowing for the creation of detailed designs with unparalleled accuracy. Concurrently, industries are experiencing a paradigm shift as productivity skyrockets and production costs plummet, thanks to the automation and versatility offered by these machines. In this guide, we will explore the hidden benefits of Cnc Laser Cutters, uncovering how they are reshaping the way we approach art and manufacturing, while providing valuable insights for those looking to integrate this innovative technology into their creative or business practices.

CNC laser cutting technology has undeniably transformed the landscape of artistry, marrying precision with creativity in unprecedented ways. Artists and designers now have the ability to explore intricate patterns and complex structures that were once limited by traditional cutting methods. This evolution empowers creators to push the boundaries of their imaginations, enabling them to produce stunning works that blend technology with fine craftsmanship. The high-speed precision of CNC laser cutters allows for a level of detail that can enhance the aesthetic appeal of various art forms, making it possible to achieve results that were previously unattainable.

Moreover, the accessibility of CNC laser cutting has democratized the art world. Emerging artists can now utilize this technology to create professional-quality pieces without the need for extensive training in traditional techniques. This shift not only fosters innovation but also encourages collaboration between artists and technologists, leading to new forms of expression. As a result, the fusion of CNC technology and artistic vision is not merely a trend; it is a dynamic evolution that redefines the boundaries of what art can be, fostering a vibrant community of creators inspired by the endless possibilities enabled by laser cutting technology.

CNC laser cutters have become invaluable tools in the realm of artistic creation, offering unmatched precision and detail that traditional methods simply cannot achieve. According to a recent report by Grand View Research, the global laser cutting market is expected to reach $5 billion by 2026, highlighting the growing demand for advanced technology in both art and industry. This surge is attributed to the ability of CNC laser cutters to create intricate designs and complex patterns with remarkable accuracy, making them a favorite among artists and designers.

The precision that CNC laser cutters provide is particularly beneficial in the production of detailed artwork, such as intricate wood carvings and bespoke metal sculptures. A study by Markets and Markets noted that artists leveraging laser cutting technology reported a 30% increase in productivity due to reduced material waste and faster turnaround times. This capability not only enhances the creative possibilities for artists but also allows for the exploration of new mediums and techniques, ultimately revolutionizing the intersection of art and technology.

As artists continue to embrace CNC laser cutting, the industry is witnessing a notable evolution in creativity and design. By unlocking new levels of detail and efficiency, these machines enable artists to push the boundaries of their craft, setting the stage for a future where technology and artistry coexist harmoniously.

CNC laser cutters are dramatically reshaping industries by introducing significant economic benefits that previously went unnoticed. As the global CNC machine market continues to expand, projected to reach a staggering market value of $77 billion by 2024, the adoption of these advanced cutting technologies is becoming increasingly crucial. Specifically, the CNC machine tools market is expected to grow by USD 21.9 billion from 2025 to 2029, driven by rising demand for high-precision and multi-axis machining centers. This growth highlights the industrial shift towards efficiency and precision, which are hallmarks of laser-cutting technology.

Moreover, the integration of artificial intelligence is propelling the evolution of CNC laser cutting, enhancing productivity and reducing costs. Notably, dynamic beam shaping technologies are unlocking new levels of productivity, making laser cutting more accessible for high-volume markets. As industries adopt these innovations, they not only improve operational efficiency but also position themselves competitively in an ever-evolving market landscape. Consequently, CNC laser cutters are not just tools but are integral to the strategic advancement of manufacturing and engineering sectors, enhancing capabilities and driving economic growth.

CNC laser cutting technology is not only revolutionizing the art and manufacturing industries but also significantly contributing to sustainability. According to a report by the International Journal of Life Cycle Assessment, CNC laser cutting can reduce material waste by up to 30% compared to traditional cutting methods. This reduction in waste is primarily due to the precision of laser technology, which allows for intricate designs with minimal excess material. Furthermore, as industries increasingly prioritize eco-friendly practices, laser cutting offers a clean and energy-efficient alternative. Laser systems often consume less energy than conventional methods, using about 15-20% less electricity, which translates into a lower carbon footprint for manufacturers.

Tips: When adopting CNC laser cutting in your production process, consider using recycled materials. Many laser cutting companies now offer eco-friendly material options, enabling artists and manufacturers to create sustainable products without compromising on quality. Additionally, optimizing designs for laser cutting can maximize material yield—focus on creating interlocking designs or modular products that minimize offcuts.

The benefits of CNC laser cutting extend beyond just material efficiency. As the industry evolves, there's an increasing emphasis on sustainable practices that align with consumer preferences. Reports indicate that 62% of consumers are more likely to support brands that prioritize sustainability. By incorporating CNC laser cutting into your workflow, you not only adhere to environmental standards but also attract a growing market segment that values eco-conscious production.

| Feature | Benefit | Eco-Friendly Aspect | Application in Art/Industry |

|---|---|---|---|

| Precision Cutting | Increased accuracy and details in designs | Minimal waste of materials | Sculptures, installations |

| Versatility | Ability to cut a variety of materials | Use of recycled materials | Furniture design, signage |

| Speed | Faster production times | Reduced energy consumption | Production of prototypes |

| Design Flexibility | Facilitates intricate and complex designs | Promotes sustainable creativity | Artistic creations, custom pieces |

| Automation Capability | Reduced need for manual labor | Lower overall waste production | Mass production of artworks |

CNC laser cutters have emerged as transformative tools across various industries, redefining the ways in which artists, designers, and manufacturers approach their work. In the realm of art, for instance, these machines empower creators to produce intricate designs with unmatched precision. According to a report by IBISWorld, the demand for laser cutting services has grown by 6.8% annually, highlighting its increasing popularity in creative fields. Artists are leveraging CNC laser technology to cut materials ranging from wood to acrylic plastic, allowing for bold experimentation and unique art pieces that were previously difficult to achieve by traditional means.

In industries like fashion and interior design, CNC laser cutters enable the development of custom patterns and fittings with remarkable efficiency. A study conducted by MarketsandMarkets forecasts that the global CNC machine market will reach $100 billion by 2025, driven partly by advancements in laser technology. Designers can now create intricate laser-cut textiles or wall panels that reflect individuality and contemporary aesthetics, enhancing both functionality and visual appeal. This versatility illustrates not only the creative potential of CNC laser cutters but also their ability to drive innovation across diverse sectors, proving essential for both artistic exploration and industrial manufacturing.

© 2025 Messer Cutting Systems, Inc.