© 2025 Messer Cutting Systems, Inc.

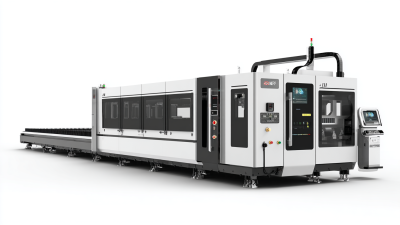

In today's fast-paced manufacturing landscape, optimizing production workflows is crucial for businesses aiming to enhance efficiency and reduce operational costs. One of the most transformative tools leading this change is the Laser CNC Machine. These advanced devices not only provide precision cutting and engraving capabilities but also streamline processes that traditionally required multiple steps and setups.

By incorporating Laser CNC Machines into your production line, you can achieve higher levels of accuracy, minimize waste, and significantly decrease lead times. This blog will explore effective strategies to leverage Laser CNC Machines, helping you unlock their full potential and elevate your manufacturing operations to new heights. Whether you're a seasoned professional or just starting, understanding how to optimize your workflow with this technology will be invaluable for maintaining a competitive edge in the industry.

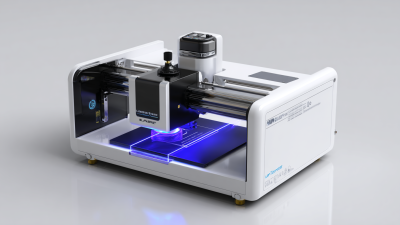

Laser CNC machines represent a transformative step in the realm of digital manufacturing technologies, offering distinctive advantages that can significantly streamline production workflows. Their ability to employ high-powered laser beams allows for precise cutting and shaping of materials, resulting in enhanced accuracy that is critical for industries ranging from defense to education. Additionally, these machines are equipped to handle various materials and complexities, showcasing their versatility in different manufacturing contexts.

One of the standout benefits of laser CNC machines is their ease of integration into existing production systems. This convergence of technology elevates operational efficiency by reducing setup times and minimizing material wastage. As organizations increasingly turn to cutting-edge solutions, educational institutions also leverage these tools to impart essential STEM skills to students, bridging the gap between theoretical knowledge and practical application. Moreover, innovations such as the blue-laser direct energy deposition combine safety and speed, promising to reshape the defense manufacturing landscape by making processes simpler and more reliable.

Analyzing and mapping your current production workflow is crucial for optimizing the use of Laser CNC machines. The first step in this process involves a thorough assessment of your existing operations. Begin by documenting each stage of production from material acquisition to the final product. This can be achieved through flowcharts or diagrams that visually represent the sequence of tasks and the time allocated to each. Identifying bottlenecks or redundancies in this visual layout will provide valuable insights into where improvements can be made.

Next, engage your team in discussions to gather their input on the workflow. Employees who are directly involved in the production process often have significant insights into inefficiencies and potential areas for enhancement. By involving them in the analysis, you not only gain a better understanding but also foster a culture of collaboration and ownership. Once you have a comprehensive map of your workflow, you can systematically address the identified issues, ultimately integrating Laser CNC machines to streamline operations further and increase overall productivity.

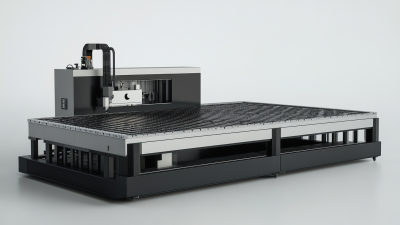

Integrating laser CNC machines into your existing production workflow can significantly enhance efficiency and precision. The first step in this integration process is to assess your current workflow. Identify bottlenecks that could benefit from the speed and accuracy of laser CNC technology. By mapping out your existing processes, you can pinpoint specific areas where laser cutting or engraving can replace or complement conventional methods, thus optimizing production time and reducing errors.

Integrating laser CNC machines into your existing production workflow can significantly enhance efficiency and precision. The first step in this integration process is to assess your current workflow. Identify bottlenecks that could benefit from the speed and accuracy of laser CNC technology. By mapping out your existing processes, you can pinpoint specific areas where laser cutting or engraving can replace or complement conventional methods, thus optimizing production time and reducing errors.

Once you have identified the potential applications of laser CNC machines, the next step is to ensure that your team is adequately trained. Familiarizing your staff with the operating mechanisms and maintenance requirements of the laser CNC machines will be crucial for a smooth transition. Furthermore, consider developing a feedback loop where operators can share insights about the machine’s performance and any issues that arise. This continuous improvement approach not only enhances the integration process but also fosters a culture of innovation within your workforce, ultimately leading to a more streamlined and productive operation.

Training staff on laser CNC operations is crucial for optimizing production workflows. Effective training programs can significantly enhance productivity and reduce error rates. According to a report by the National Institute of Standards and Technology (NIST), companies that invest in comprehensive training see a 20% increase in production efficiency. By equipping employees with the necessary skills to operate laser CNC machines, businesses can minimize downtime and ensure that projects are completed on schedule.

Best practices for training should include a blend of theoretical knowledge and hands-on experience. A survey from the Fabricators & Manufacturers Association indicates that 75% of companies that integrate practical training sessions report improved employee confidence and skill retention. Incorporating simulation software and real-world scenarios into the training process can provide employees with valuable insights and prepare them for actual operating conditions. Additionally, fostering a culture of continuous learning through regular workshops and updates can empower staff to stay current with technological advancements, ultimately leading to a more efficient and innovative production environment.

| Training Topic | Description | Duration | Frequency | Trained Staff |

|---|---|---|---|---|

| Introduction to Laser CNC | Overview of laser CNC technology and applications. | 2 hours | Onboarding | 20 |

| Safety Precautions | Training on safe operation practices and emergency response. | 3 hours | Monthly | 40 |

| Machine Operation | Hands-on training on operating laser CNC equipment. | 5 hours | Weekly | 30 |

| Maintenance Procedures | Understanding routine maintenance and troubleshooting. | 4 hours | Quarterly | 15 |

| Software Training | Training on design software integration with laser CNC. | 3 hours | Bi-weekly | 25 |

To optimize your production workflow with laser CNC machines, measuring success is paramount. Key performance indicators (KPIs) offer a quantifiable way to evaluate efficiency and effectiveness. By establishing clear metrics, such as cycle time, material waste, and throughput, businesses can pinpoint bottlenecks and streamline processes. Implementing a closed-loop evaluation system allows for continuous monitoring and adjustment, akin to advanced control mechanisms used in quantum computing and AI optimization techniques.

Incorporating modern methodologies such as random linear gate-set tomography can enhance the signal-to-noise ratio in performance measurement. Additionally, leveraging AI-driven analytics tools can assist in refining these metrics, ensuring that organizations not only capture data but also interpret it meaningfully. By focusing on workflow metrics tailored to laser CNC operations, manufacturers can achieve significant improvements in productivity, ultimately leading to increased profitability and market competitiveness.

© 2025 Messer Cutting Systems, Inc.