© 2025 Messer Cutting Systems, Inc.

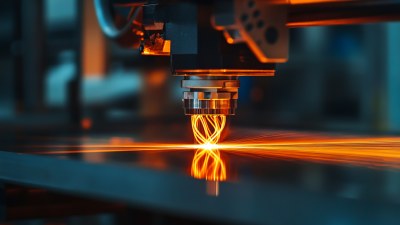

The advancements in manufacturing technology have led to the increasing adoption of specialized tools such as the Metal Laser Cutter, which has revolutionized production capabilities across various industries. According to a recent report from Markets and Markets, the global laser cutting market is projected to reach $6.99 billion by 2026, driven by the need for enhanced precision and efficiency in metal fabrication. This sophisticated machinery employs high-powered lasers to cut, engrave, and shape various types of metals, enabling manufacturers to achieve intricate designs with minimal waste and reduced lead times. Additionally, the versatility of Metal Laser Cutters allows for applications ranging from automotive to aerospace and electronics, highlighting their essential role in modern manufacturing processes. As industries continue to seek innovative solutions to meet evolving demands, the Metal Laser Cutter stands out as a pivotal tool that not only enhances productivity but also ensures the quality and precision of metal products.

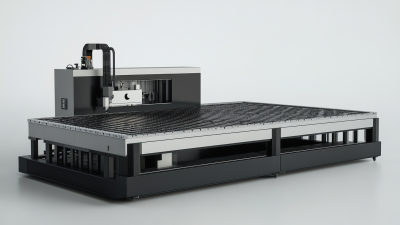

Metal laser cutters have revolutionized modern manufacturing by enhancing efficiency and precision in various industries. These advanced machines utilize focused laser beams to cut through metal materials with exceptional accuracy, allowing manufacturers to produce intricate designs and components that were previously difficult to achieve with traditional cutting methods. The ability to cut a wide range of materials, from stainless steel to aluminum, means that metal laser cutters are versatile tools that can adapt to the diverse needs of production processes.

Metal laser cutters have revolutionized modern manufacturing by enhancing efficiency and precision in various industries. These advanced machines utilize focused laser beams to cut through metal materials with exceptional accuracy, allowing manufacturers to produce intricate designs and components that were previously difficult to achieve with traditional cutting methods. The ability to cut a wide range of materials, from stainless steel to aluminum, means that metal laser cutters are versatile tools that can adapt to the diverse needs of production processes.

In addition to their cutting capabilities, metal laser cutters streamline manufacturing workflows by reducing setup times and minimizing material waste. The precision of laser cutting reduces the need for extensive post-processing, which not only saves time but also lowers operational costs. Moreover, the automation and programmability inherent in laser cutting technology allow for seamless integration into modern manufacturing systems, enabling rapid adjustments to production lines in response to changing demands. As a result, metal laser cutters are integral to enhancing overall manufacturing efficiency, supporting industries in meeting market needs with speed and superior quality.

Metal laser cutters are revolutionizing the manufacturing industry by providing unprecedented levels of precision and speed. The underlying technology utilizes high-powered lasers to accurately cut through various types of metal, minimizing the risk of errors and material wastage. This process transforms traditional manufacturing methods by enabling complex designs that were previously impossible or extremely time-consuming. The efficiency of laser cutting means that manufacturers can meet tight deadlines while ensuring superior quality in their products.

Tip: When selecting a metal laser cutter, consider the wattage of the laser, as higher wattage typically allows for faster cutting of thicker materials. Additionally, make sure to evaluate software compatibility to ensure seamless integration with your existing design tools.

Another key aspect of metal laser cutting technology is its ability to enhance automation in manufacturing processes. Coupled with advanced robotics and CNC (computer numerical control) systems, metal laser cutters can operate continuously, contributing to increased productivity and reduced labor costs. This automation not only speeds up production cycles but also enhances safety by reducing the need for manual handling of hazardous materials.

Tip: Regular maintenance of your laser cutting equipment is crucial for maintaining precision and extending the machine's lifespan. Schedule routine inspections and replace worn-out components promptly to avoid costly downtime.

Laser cutting technology has significantly transformed manufacturing processes by enhancing efficiency and reducing waste. The economic impact of laser cutting on production costs is profound, as it allows for precise cuts that minimize material waste, ultimately lowering the overall expenses of manufacturing. This technology enables manufacturers to optimize resource utilization, which is increasingly crucial in today's environmentally conscious market.

Moreover, as sustainability becomes a pivotal focus in manufacturing, laser cutting contributes to improving solid waste management systems. Through methods like Wire and Arc Additive Manufacturing (WAAM), manufacturers can evaluate and enhance both environmental and economic performances using Life Cycle Assessment (LCA). The integration of such technologies allows for better resource management and energy consumption, paving the way towards more sustainable production practices. Therefore, the advancements in laser cutting not only drive down costs but also reinforce a commitment to waste reduction and environmental responsibility in manufacturing.

The integration of artificial intelligence (AI) and automation in metal laser cutting is revolutionizing manufacturing processes, leading to enhanced efficiency and output. By leveraging advanced algorithms, manufacturers can optimize cutting paths, reduce material waste, and improve accuracy. AI-driven systems analyze operational data in real-time, enabling machines to adapt to varying conditions and ensuring consistent quality. This technological evolution not only minimizes human error but also accelerates production times, making it a game-changer in the competitive landscape of manufacturing.

As the global fiber laser market is projected to expand from $4.63 billion in 2025 to $10.75 billion by 2032 at a compound annual growth rate of 12.8%, the focus on integrating these innovations becomes even more paramount. Manufacturers are increasingly adopting these technologies to stay ahead, as automated solutions enhance not only productivity but also the ability to handle complex designs. The rise in demand for high-precision and efficient manufacturing aligns perfectly with the capabilities offered by AI and automated laser cutting machines, setting the stage for a new era in industrial production.

The landscape of manufacturing is being transformed by advancements in metal laser cutting technology. As we move towards 2025, the metal manufacturing equipment market is projected to grow from $64.64 billion in 2025 to $82.78 billion by 2032, reflecting a compound annual growth rate of 3.6%. This growth is driven by the demand for precision and efficiency in production processes, particularly in metal processing sectors.

Laser cutters provide unmatched advantages in speed and accuracy, allowing manufacturers to reduce production times and material waste. Reports indicate that, from 2015 to 2024, over 3,973 patents related to sheet metal processing have been filed in China, showcasing the rapid advancements and innovations in this field. Moreover, the demand for laser systems is expected to reach a staggering market size of 36.85 billion yuan by 2024.

**Tip:** Embracing laser cutting technology can significantly enhance your manufacturing capabilities and open doors to new markets. Consider investing in laser cutter systems to stay competitive in the evolving landscape.

The focus on high-end applications indicates a shift towards greater automation and precision in manufacturing processes. As future trends unfold, industries investing in advanced laser technologies will likely gain a competitive edge and lead the charge in operational efficiency.

**Tip:** Regularly update your equipment and training to incorporate the latest laser cutting technologies and techniques, which can improve production rates and reduce operational costs.

| Feature | Description | Impact on Manufacturing | Future Trends |

|---|---|---|---|

| Precision Cutting | Laser cutters achieve high levels of accuracy and intricate designs. | Reduce material waste and improve product quality. | Increasing integration with CAD technologies for enhanced design processes. |

| Speed | High cutting speeds reduce overall production time significantly. | Faster turnarounds on projects lead to better responsiveness to market demands. | Emergence of faster laser technology and automation systems. |

| Material Versatility | Can cut various metals including steel, aluminum, and copper. | Diverse applications across industries from automotive to aerospace. | Development of lasers that can handle more exotic materials. |

| Automation | Integration with automated systems for loading, cutting, and unloading. | Increases efficiency and lowers labor costs. | Greater reliance on AI to optimize cutting processes. |

| Safety | Incorporates advanced safety features to protect operators. | Minimizes workplace accidents and injuries. | Future enhancements with comprehensive monitoring systems. |

© 2025 Messer Cutting Systems, Inc.