© 2025 Messer Cutting Systems, Inc.

As we look ahead to 2025, the landscape of industrial manufacturing is poised for significant transformation, particularly in the realm of laser cutting technology. The advancements in Laser Cutting Machines promise not only enhanced precision and efficiency but also the ability to handle an increasingly diverse range of materials with minimal waste. Businesses are faced with the challenge of selecting the best laser cutting machine that aligns with their production needs and budget constraints. With innovations such as fiber lasers and automated systems on the horizon, understanding future trends in this field will be crucial for companies aiming to maintain a competitive edge. This blog will explore the pivotal developments anticipated in laser cutting technology and provide guidance on how to choose the right Laser Cutting Machine to drive success in your organization.

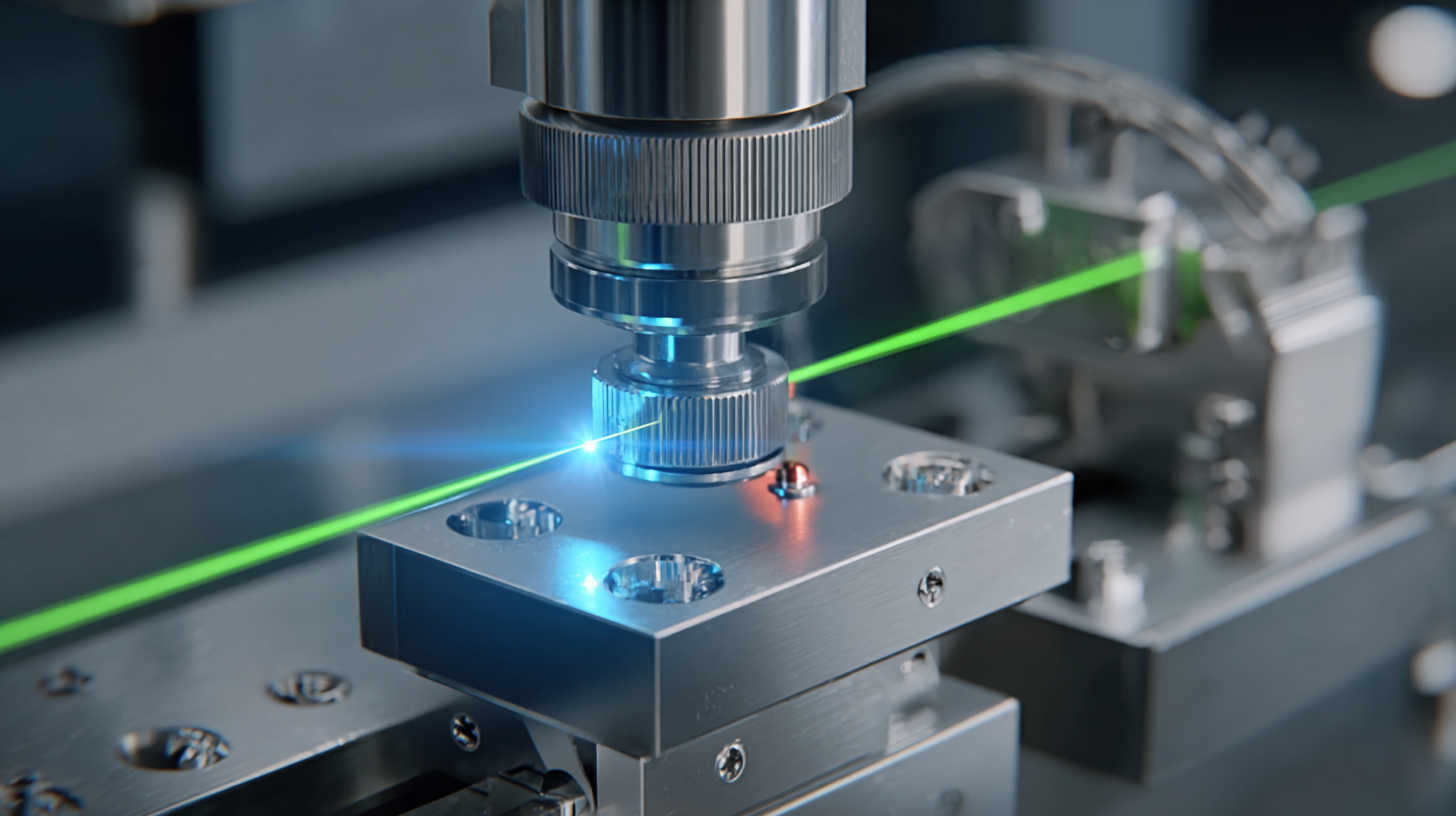

As the laser cutting industry evolves, several emerging technologies are poised to shape its future in 2025 and beyond. With the laser technology market projected to reach USD 37.26 billion by 2032, advancements in laser cutting machinery are becoming increasingly critical for businesses looking to enhance efficiency and precision. Modern laser-cutting machines utilize high-powered laser beams to achieve complex cuts and shapes, which are essential in sectors ranging from automotive to aerospace.

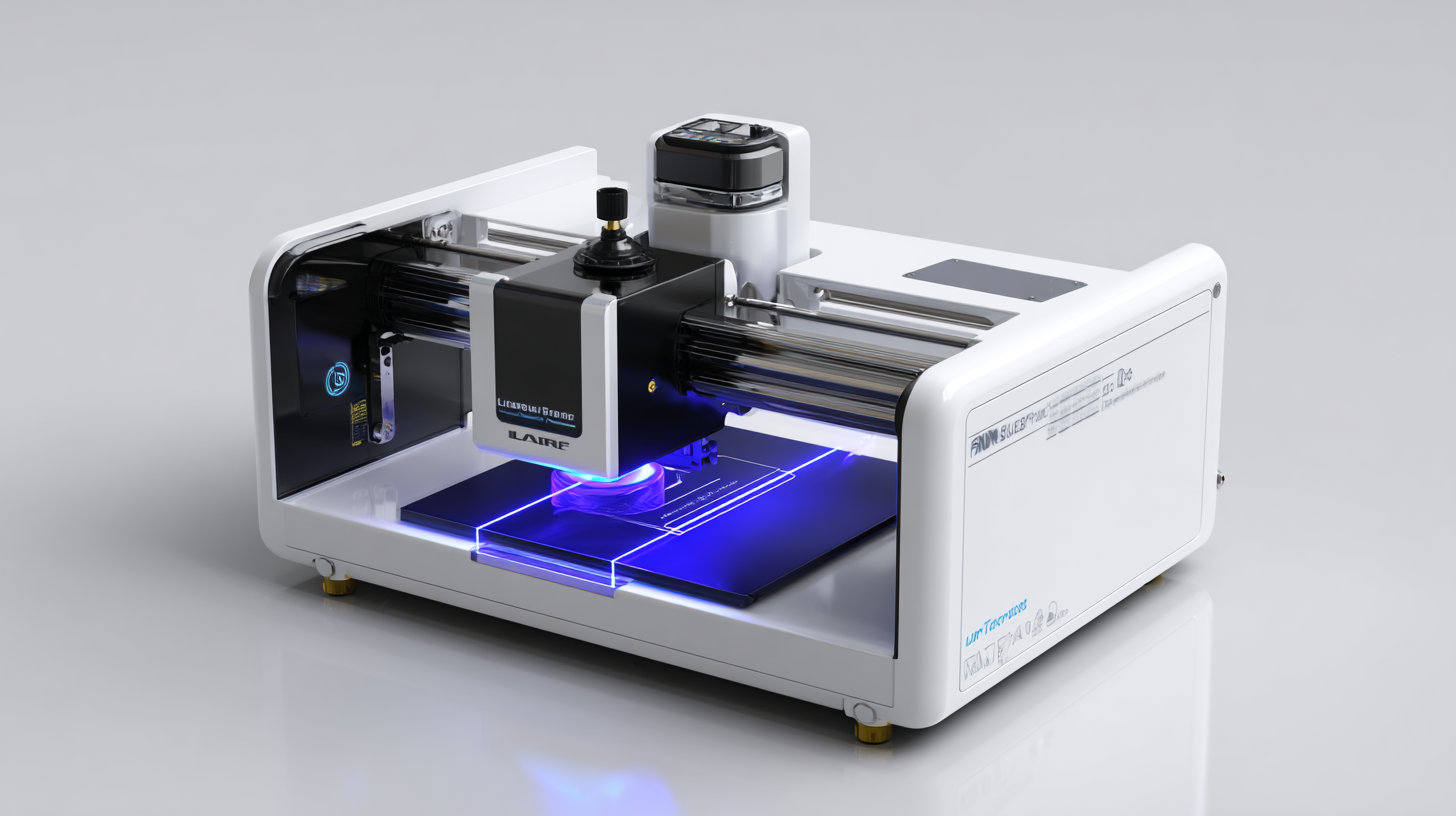

In addition, innovative products are entering the market, such as multifunctional devices that can seamlessly switch between 3D printing and laser cutting. These versatile machines not only save time but also reduce the need for multiple pieces of equipment, making them ideal for small to medium-sized enterprises. The increasing demand for high-efficiency cutting solutions will push manufacturers to refine their technologies, ensuring they meet the growing requirements of various industries. Observing the latest trends can help businesses make informed decisions when selecting the best laser cutting machines for their operations.

As laser cutting technology continues to evolve, selecting the right machine for your business becomes increasingly critical. Key factors to consider include the type of laser technology, with options such as fiber, CO2, and solid-state lasers, each offering unique capabilities tailored to different applications. Understanding these distinctions will help businesses align the equipment with their operational needs and production goals.

Market insights reveal that the global laser cutting equipment sector is poised for significant growth, further propelled by post-COVID-19 recovery trends. The increasing demand for precision cutting in industries like packaging and manufacturing highlights the importance of investing in advanced laser technologies that not only boost efficiency but also enhance sustainability. As enterprises aim to meet the rising expectations of consumers for multifunctional and aesthetically appealing products, selecting a laser cutting machine that integrates innovative features will become a key differentiator in the marketplace.

The future of laser cutting technology is poised for a transformation driven by advancements in automation. As industries continue to demand higher efficiency and precision, integrating automated systems into laser cutting processes will become essential. Automating laser cutting not only optimizes production speed but also enhances consistency in output, reducing the margin for error that often arises from manual operation. This shift allows businesses to allocate workforce resources more strategically, focusing human talent on complex tasks while machines handle repetitive functions.

Moreover, the incorporation of advanced technologies such as artificial intelligence and machine learning into laser cutting solutions will further refine automation capabilities. These technologies can analyze real-time data, enabling the equipment to adjust settings dynamically for optimal performance based on varying material types and thicknesses. The result is a more adaptive and intelligent manufacturing environment, where laser cutting machines can self-correct and ensure the highest quality cuts, minimizing waste and downtime. For businesses looking to stay competitive, selecting a cutting machine that incorporates these automation features will be crucial to harnessing the full potential of future laser cutting technologies.

When considering an upgrade to your laser cutting equipment, understanding the cost-efficiency and return on investment (ROI) is crucial for making informed decisions. A high-quality laser cutting machine can dramatically improve productivity and reduce operational costs over time. This translates not just to faster production rates but also to less material wastage due to precision cutting capabilities. Analyzing the total cost of ownership, including maintenance, energy consumption, and potential downtime, will provide a clearer picture of your investment's long-term benefits.

Tip 1: Before making a purchase, conduct a comprehensive ROI analysis. Calculate not just the upfront costs but also the savings in labor and materials over time. This data will help illustrate the machine’s financial impact on your business.

Tip 2: Evaluate the available technology and features of laser cutting machines. Advanced options such as automation and smart technology can enhance efficiency, further improving ROI. Take note of user-friendly interfaces that reduce training times for staff.

Investing in a more efficient laser cutting system can yield significant financial rewards when approached strategically. By focusing on the long-term cost efficiency, businesses can make upgrades that align with their growth goals.

The laser cutting industry is undergoing transformative changes driven by sustainability trends that are shaping manufacturing processes for the future. As we approach 2025, it is essential to assess how advancements in technology are influencing the choice of laser cutting machines. Reports indicate that the cutting fluid market, which enhances machining efficiency, is projected to grow significantly by 2035. This underscores the industry's push towards optimizing productivity while minimizing environmental impact, an ethos that also extends to laser cutting technologies.

Additionally, innovations such as handheld water jet cutting machines are bridging the gap between precision and portability, aligning with sustainability objectives. By reducing waste and energy consumption, these developments contribute to more sustainable manufacturing practices. Industry 5.0 is also emerging, focusing on integrating IoT, robotics, and AI to enhance resource optimization across sectors, including food manufacturing. This synergy of smart technologies and sustainability is driving forward-thinking businesses to prioritize eco-friendly solutions when selecting their cutting equipment for the future.

© 2025 Messer Cutting Systems, Inc.