© 2025 Messer Cutting Systems, Inc.

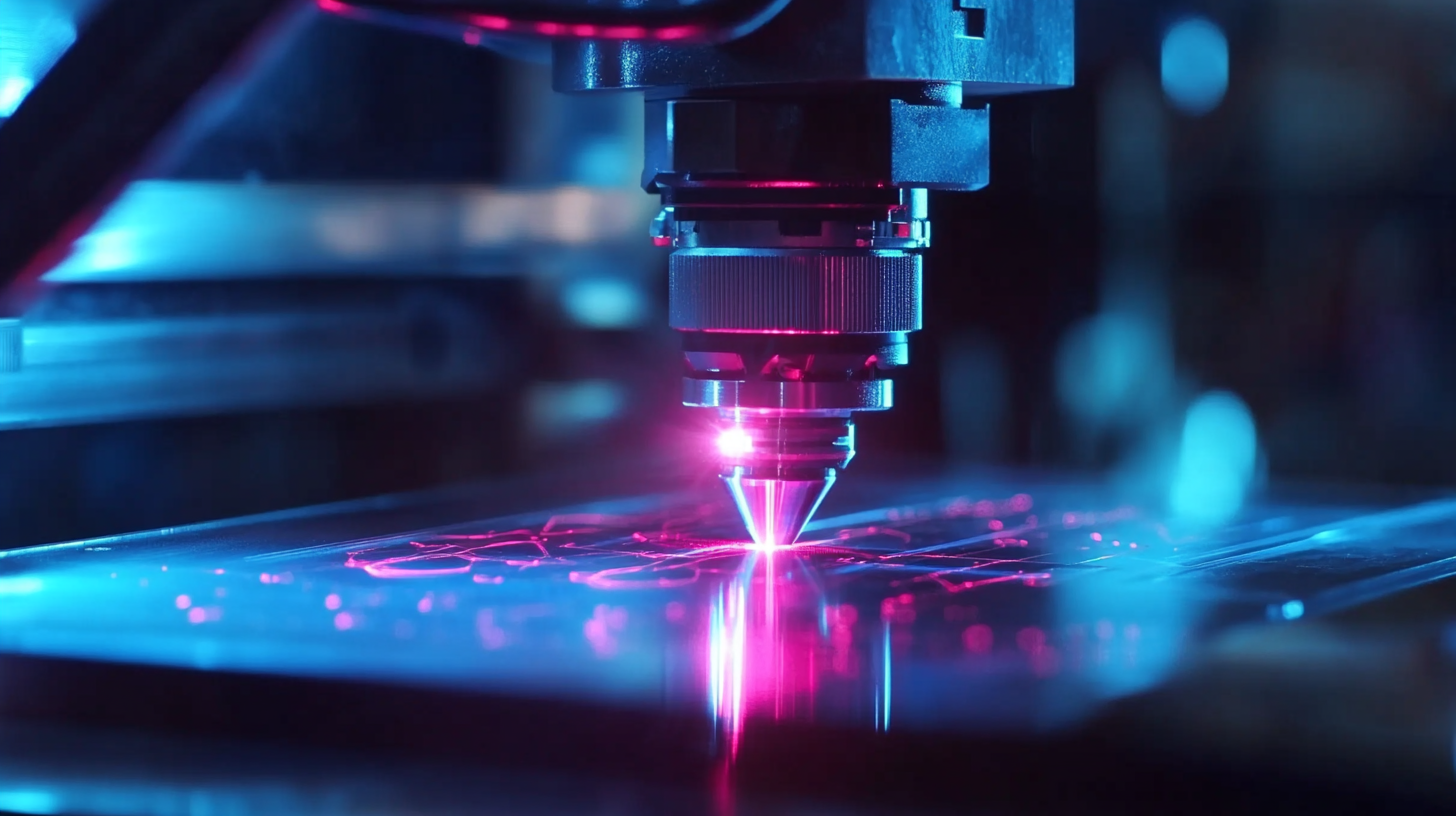

As industries continue to evolve technologically, the fiber laser machine stands out as a critical tool driving advancements in manufacturing and materials processing. According to a report by MarketsandMarkets, the global fiber laser market is projected to reach $4.85 billion by 2025, indicating a robust growth trajectory fueled by increasing demand for precision and efficiency in laser cutting and welding applications. This surge in the adoption of fiber laser machines is reshaping production standards across various sectors, necessitating an understanding of the industry benchmarks that define best practices.

As we look toward 2025, identifying and adhering to these standards will be vital for manufacturers aiming to enhance productivity and maintain competitive advantages in a rapidly changing marketplace. This blog will explore the key trends and guidelines essential for optimizing fiber laser machine production, setting the stage for the next wave of technological innovation.

When selecting the best fiber laser machines, several key characteristics and performance metrics should be considered. First and foremost is the laser power, which typically ranges from 500 watts to several kilowatts. Higher power levels enable faster cutting speeds and the ability to handle thicker materials. Additionally, the wavelength of the laser light, typically around 1064 nm for fiber lasers, allows for effective absorption by a variety of metals, ensuring precise cutting and engraving.

Another crucial aspect is the machine’s speed and efficiency. Evaluate the maximum cutting speed, as well as acceleration capabilities, to determine how quickly the machine can complete tasks. The integration of advanced motion control systems plays a significant role in enhancing speed and ensuring high-quality results with minimal deviation. Moreover, the duty cycle—how long the machine can operate continuously before needing a cooldown—affects productivity. A machine designed for heavy-duty use with optimized cooling systems can maintain high throughput, minimizing downtime and increasing overall project efficiency. Choosing a fiber laser machine based on these characteristics and metrics ultimately leads to superior performance in various industrial applications.

The demand for fiber laser technology in manufacturing is on the rise, driven by its remarkable efficiency and precision. According to a recent market analysis by Fortune Business Insights, the global fiber laser market is expected to reach $8.19 billion by 2027, growing at a CAGR of 10.5% from 2020. This surge is largely attributed to the technology's application in various sectors, including automotive, aerospace, and electronics, where high-quality cutting and engraving are essential.

Adopting fiber laser systems comes with significant benefits. Companies can improve production speeds while reducing operational costs. Moreover, fiber lasers have a longer lifespan and lower maintenance requirements compared to traditional laser technologies, making them an attractive investment for manufacturers.

Tips: To maximize the efficiency of your fiber laser machine, ensure regular maintenance checks and keep the optics clean. Additionally, staying updated on software advancements can greatly enhance your machine's capabilities. Lastly, consider investing in staff training to optimize the laser's capabilities and minimize errors during operation.

In the rapidly evolving field of fiber laser technology, adhering to quality standards is essential for ensuring that machines meet the high expectations of various industries. Certifications play a pivotal role in this process, with ISO 9001 being one of the most recognized benchmarks for quality management systems. This certification ensures that manufacturers implement systematic processes to enhance product quality and customer satisfaction. Compliance with such standards not only boosts credibility but also streamlines production practices, ultimately leading to more reliable and efficient fiber laser machines.

Moreover, industry-specific certifications, such as CE marking and FDA approvals, are crucial for targeting specific markets. CE marking signifies that a product meets EU safety, health, and environmental protection requirements, while FDA approvals are essential for devices intended for medical or food-related applications.

By aligning their production processes with these stringent regulations, manufacturers can enhance their marketability and ensure that their fiber laser machines are not only high-performing but also safe and compliant. Understanding and implementing these certifications can significantly contribute to a manufacturer’s reputation and success in the competitive landscape of fiber laser technology.

The economic impact of fiber laser solutions extends far beyond initial investment costs. Businesses integrating fiber laser machines into their production lines often experience significant cost savings due to increased efficiency and reduced operational expenses. These machines offer a faster cutting speed and lower power consumption compared to traditional laser technologies, making them an attractive option for manufacturers aiming to enhance productivity while minimizing costs. This efficiency translates directly into a more favorable return on investment (ROI), as companies can produce higher quality products with less downtime and fewer wasted materials.

Moreover, the versatility of fiber laser machines allows them to adapt to various applications, from metal cutting to engraving, significantly broadening their utility across industries. This adaptability helps businesses streamline their operations, further driving down costs. As companies justify their investments by demonstrating tangible savings and increased output, fiber laser technologies are quickly becoming essential assets in achieving long-term financial goals. The cumulative effect of these economic benefits positions fiber laser solutions as a crucial component for businesses looking to thrive in a competitive market environment.

| Parameter | Description | Average Value | Impact on ROI (%) |

|---|---|---|---|

| Initial Investment | Cost of acquiring a fiber laser machine | $80,000 | - |

| Operational Costs | Monthly expenses including maintenance and utilities | $1,500 | - |

| Production Speed | Average production speed in units per hour | 45 units | 20% |

| Material Utilization | Percentage of material used effectively | 95% | 15% |

| Typical Lifespan | Average operational lifespan of the machine in years | 10 years | 30% |

| Revenue Increase | Annual revenue increase after implementation | $50,000 | 40% |

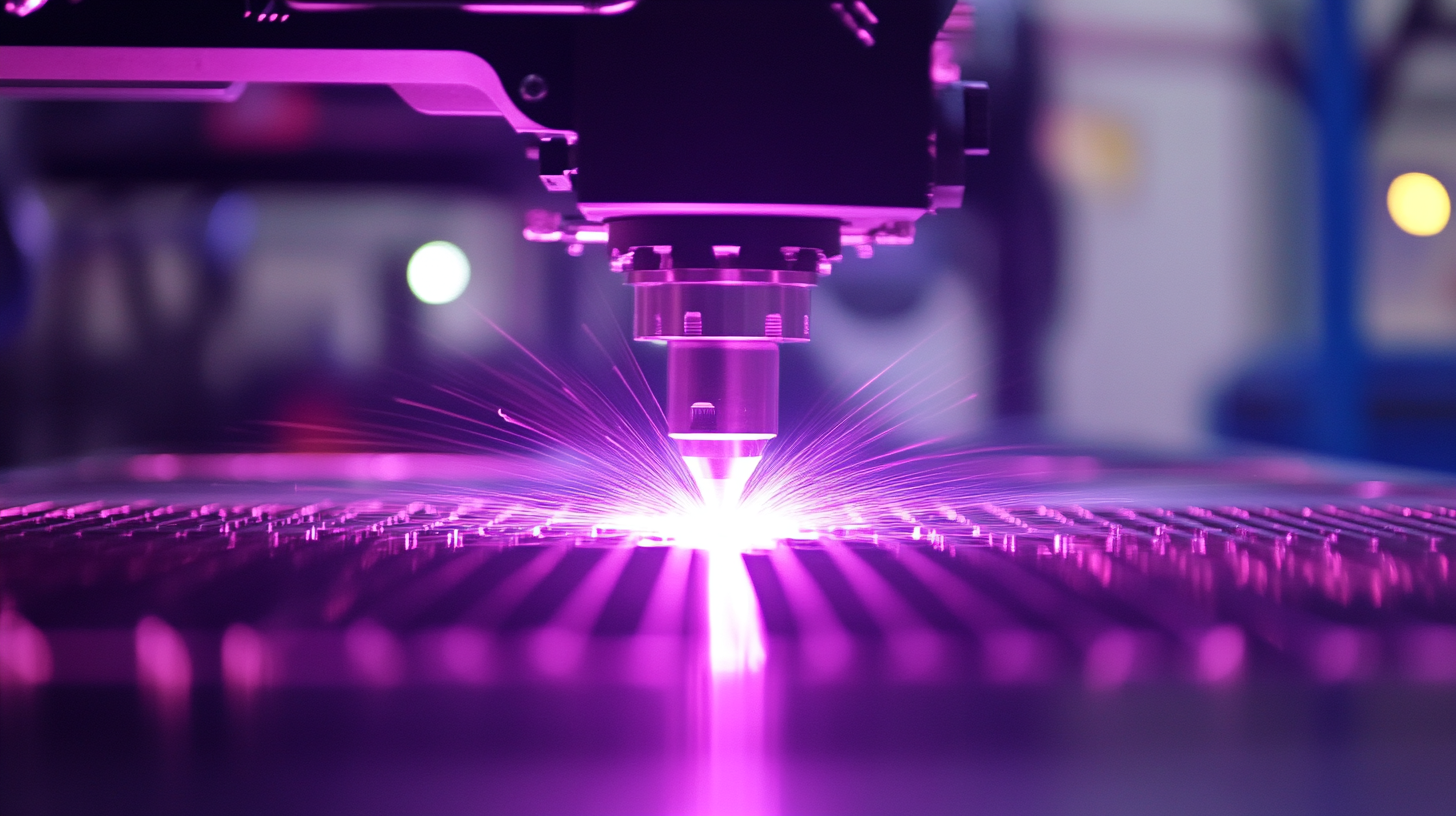

The production of fiber laser machines has witnessed significant technological innovations in recent years, shaping the industry standards and enhancing overall efficiency. One of the key advancements is the integration of intelligent software solutions that optimize the laser cutting process. These programs use artificial intelligence and machine learning algorithms to analyze cutting profiles and materials in real-time, allowing for tailored adjustments that increase precision and reduce waste. As a result, manufacturers are now able to produce complex designs with exceptional accuracy, catering to a diverse range of applications, from automotive to aerospace.

Another notable development is the improvement in fiber laser technology itself, primarily through increased power and enhanced beam quality. High-energy lasers enable faster cutting speeds while maintaining a clean edge and reducing the heat affected zone. Innovations like modular laser systems also provide flexibility for manufacturers, allowing them to scale their operations based on specific production demands. Furthermore, advancements in cooling systems and energy efficiency are reducing operational costs, making fiber laser machines not only a reliable choice but also a cost-effective solution for various industries.

© 2025 Messer Cutting Systems, Inc.