© 2025 Messer Cutting Systems, Inc.

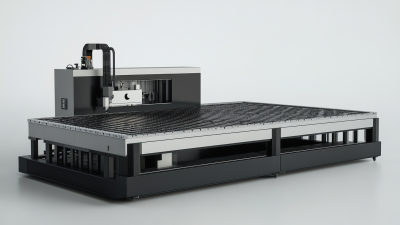

As the manufacturing landscape continues to evolve, the emergence of cutting-edge technologies is driving significant improvements in efficiency and productivity. Among these innovations, the "Laser Engraver and Cutter" plays a pivotal role, facilitating intricate designs and high-precision cuts that were once unimaginable. According to a report by MarketsandMarkets, the global laser cutting market is projected to grow from $3.99 billion in 2020 to $5.77 billion by 2025, at a CAGR of 7.7%. This surge is indicative of the increasing adoption of laser technology across various sectors including automotive, aerospace, and consumer goods. In this blog, we will explore five digital innovations that are revolutionizing laser engraving and cutting processes, thereby enhancing manufacturing efficiency and reshaping production methodologies for businesses worldwide.

The manufacturing sector is experiencing a significant shift with the introduction of emerging laser technologies that enhance efficiency and precision. One of the most notable advancements is the integration of AI-driven software in laser engravers and cutters. This technology allows for real-time monitoring and adjustments, drastically reducing material waste and ensuring that products meet exact specifications. As manufacturers seek to streamline their operations, this AI-enhanced capability offers a competitive edge that is becoming increasingly vital.

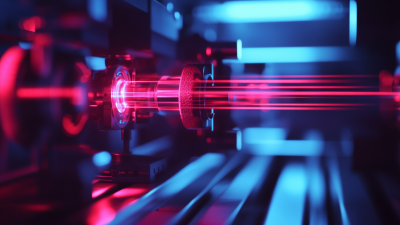

Another noteworthy innovation is the development of high-speed fiber lasers. These lasers not only provide unparalleled cutting speeds but also improve energy efficiency compared to traditional CO2 lasers. The ability to cut through a variety of materials, such as metals and plastics, with high precision allows manufacturers to expand their product lines while maintaining lower operational costs. Additionally, the evolution of portable laser engraving systems underscores the trend toward versatility and convenience, empowering small and medium enterprises to adopt advanced manufacturing techniques without significant capital investment.

The laser engraving and cutting industry is undergoing a significant transformation thanks to recent digital innovations that significantly enhance manufacturing efficiency. One of the most notable advancements is the integration of artificial intelligence (AI) and machine learning algorithms, which optimize cutting speeds and precision. These technologies can analyze material behaviors in real-time, adjusting settings on the fly to improve both the quality and speed of engravings. This capability allows manufacturers to streamline their workflows, reduce waste, and increase throughput dramatically.

In addition to AI enhancements, the latest laser systems come equipped with advanced cooling technologies and improved beam quality, which further boost operational speed. For instance, new designs utilize superior optics to produce cleaner cuts at higher speeds, catering to increasing demand in both small and large-scale manufacturing settings. As a result, manufacturers are not only meeting production targets more efficiently but are also able to explore new applications for laser technology.

This blend of innovation and efficiency is set to redefine industry standards, paving the way for a future where laser systems are integral to smart manufacturing practices.

In manufacturing, the adoption of advanced laser engravers and cutters has led to significant cost savings by improving material utilization and reducing waste. These digital innovations enable manufacturers to refine their processes, using precise cutting techniques that minimize scrap material. By employing software that optimizes layouts and production runs, companies can ensure that every inch of material is used effectively. This not only drives down material costs but also promotes sustainability, an essential factor in modern manufacturing practices. Tip: To maximize material utilization, invest in software tools that analyze and optimize your cutting patterns. This can lead to a substantial reduction in waste and increase your overall efficiency.

Another advantage of modern laser technologies lies in their ability to operate at high speeds without sacrificing precision. This speed enhances production cycles, allowing for faster turnaround times and better responsiveness to market demands. As a result, manufacturers can produce items more economically while also maintaining high-quality standards. Tip: Regularly train your staff on the latest technology and best practices in operating laser equipment. A well-informed team can significantly improve your material handling processes, further cutting down on waste and increasing efficiency.

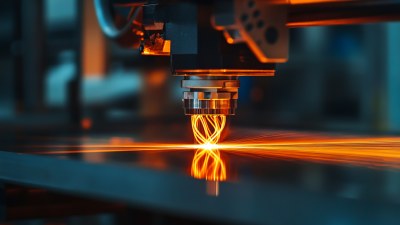

The precision engineering of laser engravers and cutters has undergone significant advancements, revolutionizing the manufacturing sector. Recent industry reports indicate that the accuracy of laser systems has improved dramatically, with some high-end models achieving repeatability levels as low as ±0.01 mm. This exceptional precision not only enhances product quality but also reduces waste, a key factor in today’s competitive market. In fact, manufacturers utilizing advanced laser technologies reported a 30% reduction in material waste, contributing to both cost savings and sustainability efforts.

The precision engineering of laser engravers and cutters has undergone significant advancements, revolutionizing the manufacturing sector. Recent industry reports indicate that the accuracy of laser systems has improved dramatically, with some high-end models achieving repeatability levels as low as ±0.01 mm. This exceptional precision not only enhances product quality but also reduces waste, a key factor in today’s competitive market. In fact, manufacturers utilizing advanced laser technologies reported a 30% reduction in material waste, contributing to both cost savings and sustainability efforts.

Moreover, the integration of digital innovations such as AI-driven error detection algorithms has taken quality control to the next level. According to a study by the International Laser Association, systems equipped with automated feedback mechanisms saw an increase in production efficiency by over 25%. This evolution in laser technology allows manufacturers to maintain high standards across various materials, from metals to plastics, ensuring that every product meets customer specifications. As the demand for precision in manufacturing continues to rise, these innovations are setting new benchmarks for quality and accuracy in the industry.

The integration of automation in laser engraving and cutting processes has revolutionized how manufacturers approach production. Smart technology streamlines operations, enabling manufacturers to achieve unprecedented levels of efficiency. By incorporating sensors and automated workflow systems, laser engravers and cutters can now execute tasks with remarkable precision and speed. This automation minimizes human error and reduces downtime, allowing for continuous operation and faster turnaround times.

Furthermore, data analytics plays a vital role in enhancing laser processes. By collecting real-time data, manufacturers can monitor machine performance and identify bottlenecks in production. Advanced algorithms can predict maintenance needs before equipment failure occurs, thereby optimizing operational efficiency. This proactive approach not only saves costs associated with unexpected breakdowns but also maximizes productivity by keeping machines running smoothly.

As smart technology continues to evolve, the possibilities for laser engraving and cutting are expanding. From enhanced productivity to improved accuracy, automation integration is reshaping the landscape of manufacturing, ensuring that companies can meet the growing demands of today's market while maintaining high-quality standards. The future of manufacturing is undoubtedly bright, with laser technology at the forefront of innovation and efficiency.

© 2025 Messer Cutting Systems, Inc.