© 2025 Messer Cutting Systems, Inc.

Die Casting Molds play a crucial role in the manufacturing industry. They enable the production of complex shapes with high precision. According to a recent report by MarketsandMarkets, the die casting market is projected to reach $26.09 billion by 2026. This growth reflects the higher demand for lightweight components across various sectors.

John Smith, a leading expert in die casting technologies, emphasizes, “Die casting molds are essential for achieving efficiency and accuracy in production processes.” His insights highlight the vital function of these molds in reducing waste and improving production speed. However, maintaining these molds can be challenging.

The intricacies involved in designing and maintaining die casting molds can lead to significant costs. Despite advances in technology, many companies struggle with mold wear and tear. This ongoing issue calls for a deeper investigation into best practices in the industry. Reflecting on these challenges can drive innovation and improvements in die casting processes.

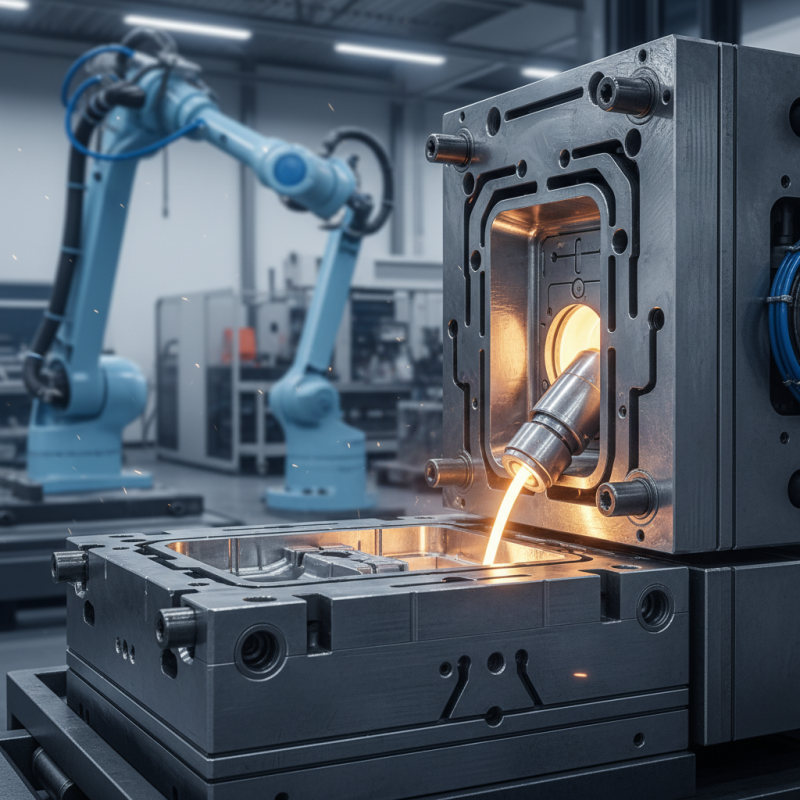

Die casting molds are essential in manufacturing. They are intricate tools designed to shape molten metal into specific forms. The process involves forcing the metal into the mold under high pressure. This ensures precision and repeatability in the final product.

Research shows that the die casting industry is projected to reach a market value of $12.31 billion by 2027. This growth highlights the significance of die casting across various sectors. Whether for automotive parts or consumer goods, the demand for durable and lightweight components is driving this industry.

However, creating die casting molds is not without challenges. The initial cost can be high, making it risky for smaller companies. Precision machining and careful design are necessary to avoid defects. Even minor errors can lead to costly waste. Therefore, constant revision and innovation in mold design are crucial to meet industry standards. This is a continuous process of improvement and reflection within the die casting community.

| Mold Type | Material | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Cold Chamber Die Casting | Aluminum, Zinc | Automotive parts, Industrial components | High precision, Suitable for high melting point metals | Lower production rate, More complex machinery |

| Hot Chamber Die Casting | Zinc, Magnesium | Consumer products, Electronics | Faster production, Lower equipment cost | Limited to low melting point metals |

| Multi-Cavity Molds | Steel, Aluminum | High volume production items | Increased efficiency, Economies of scale | Higher initial costs, Design complexity |

| Single Cavity Molds | Steel, Iron | Prototype designs, Low volume products | Lower upfront costs, Simplified design | Slower production, Less efficient for bulk |

Die casting molds are essential in manufacturing a wide range of metal parts. They vary significantly in design and function. There are two main types: horizontal and vertical molds. Horizontal molds are typically easier to use. They allow for efficient metal flow, which ensures better quality. Vertical molds, however, are more complex. They are often used for intricate designs requiring tighter tolerances.

According to industry reports, the global die casting market is expected to reach over USD 20 billion by 2025. This growth highlights the demand for diverse mold designs. Creating high-quality die casting molds can be challenging. Many manufacturers struggle to balance quality and efficiency. Factors like cooling rates and mold materials can dramatically impact production. Data shows that optimal cooling can reduce cycle times by 10-15%. Yet, not all molds achieve this optimization.

Moreover, mold maintenance is critical for long-term success. A well-maintained mold can last for thousands of cycles. Neglecting maintenance often leads to defects. This results in higher costs and wasted materials. As manufacturers explore advanced techniques, they face many trade-offs. Embracing innovation while maintaining cost-effectiveness is not straightforward.

Die casting is a precise manufacturing process. It involves forcing molten metal into a mold. The metal is usually aluminum, zinc, or magnesium. The molds are made from durable materials, allowing them to withstand high pressure.

The die casting process starts with melting the metal. Next, the molten metal flows into the mold cavity. As it cools, it solidifies into the desired shape. This process can create intricate designs with smooth finishes. However, imperfections can occur. Sometimes air bubbles form, leading to defects. Inconsistencies in temperature may cause issues too.

After cooling, the mold opens to release the cast part. It is then trimmed to remove excess material. While die casting is efficient, it's not without challenges. Proper maintenance of the molds is crucial. A poorly maintained mold can drastically reduce the quality. Frequent inspections are necessary to ensure optimal performance. Balancing speed and quality can be tricky in this process.

This chart displays the cycle time (in seconds) for different die casting materials. As seen, aluminum has a competitive cycle time among common die casting materials, followed closely by zinc and magnesium.

Die casting molds are critical in manufacturing. The materials used to create these molds greatly influence their performance and lifespan. Typically, molds are made from metals such as steel and aluminum. Steel molds are durable, offering high resistance to wear and tear. Aluminum molds are lighter and conduct heat well, making them suitable for certain applications.

Certain types of steel, like tool steel, are often used for their strength. These materials can withstand high pressure. However, they may be prone to corrosion if not treated properly. On the other hand, aluminum molds can be quite expensive, yet they cool faster, providing efficiency in production. The choice of material often hinges on the project's specific demands.

It is essential to consider the trade-offs involved. A strong mold may be heavy and harder to maneuver. Conversely, a lightweight mold might not endure under extreme conditions. Each material comes with its own pros and cons, leading to reflections on the best possible choice for the situation at hand. The ongoing quest to enhance mold materials is ever-present, as innovation in die casting continues.

Die casting molds are vital in manufacturing processes that create intricate metal parts. Their primary advantage lies in producing high volumes of uniform products with excellent surface finish and dimensional accuracy. According to the Global Die Casting Market report, the industry is projected to reach $75 billion by 2028, driven by increased demand in sectors like automotive, aerospace, and consumer electronics.

The applications of die casting molds are extensive. They are widely used to create components such as engine blocks, transmission housings, and intricate electronic housings. Each mold is designed for efficiency and precision, offering faster production rates than traditional methods. However, creating a quality mold requires a significant initial investment and ongoing maintenance. This challenge can be daunting for smaller manufacturers.

Tip: Regular maintenance checks can extend the mold's lifespan. Conducting inspections before and after production can prevent larger issues down the line.

Despite their benefits, die casting molds have limitations. The materials cost can be high, and the process itself requires skilled labor. Many businesses struggle with balancing quality and efficiency. Investing in advanced technology might help, but it often comes with its own set of challenges. It’s crucial to evaluate the long-term benefits against the upfront costs.

Tip: Consider prototyping before full-scale production. This approach can save both time and resources while ensuring the design meets specifications.

© 2025 Messer Cutting Systems, Inc.