© 2025 Messer Cutting Systems, Inc.

In today's fast-paced manufacturing landscape, the demand for precision and efficiency has never been higher, especially in global supply chains. As reported by industry analysts, the market for laser cutting services is anticipated to grow significantly, reaching approximately $4.5 billion by 2027, fueled by advancements in technology and increasing applications across various sectors. Laser cutting services offer unparalleled advantages, including reduced material waste, enhanced design flexibility, and the ability to work with a variety of materials, from metals to plastics. However, choosing the right provider is critical to maximizing these benefits and ensuring a seamless supply chain operation. This guide aims to navigate the complexities of selecting the most suitable laser cutting services tailored to your specific needs, ensuring that your business remains competitive in a rapidly evolving global market.

Laser cutting services are becoming increasingly vital in global supply chains, offering key advantages that enhance efficiency and precision. With the rapid development of advanced technology in the laser processing equipment manufacturing industry, companies can now achieve higher quality outputs and reduced operational costs. The laser cutting process allows for intricate designs and it operates with minimal waste, making it an eco-friendly choice for manufacturers looking to improve sustainability in their production.

**Tips for Choosing the Right Laser Cutting Services:**

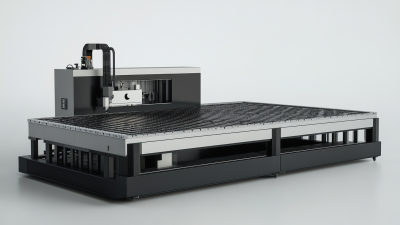

1. Evaluate the technical capabilities of the service provider. Ensure they can handle the specific materials and thicknesses required for your projects.

2. Consider the provider's delivery timeframes. Having reliable timelines for production can greatly impact your supply chain efficiency.

3. Look for providers with strong after-sales support. Maintenance and technical assistance can be crucial for minimizing downtime in your manufacturing processes.

By leveraging the strengths of laser cutting services, companies can streamline their supply chain operations and maintain a competitive edge in the marketplace. With continuous advancements in this field, the potential for innovation and growth is substantial.

As the demand for precision and quality control in manufacturing continues to rise, laser cutting technology has emerged as a pivotal solution in enhancing supply chain efficiency. The global laser technology market surpassed $19.3 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of approximately 5% from 2024 to 2032, driven by expanding applications in communication technology. This growth highlights the increasing reliance on advanced laser cutting services in achieving accurate and high-quality production standards, particularly in high-tech industries.

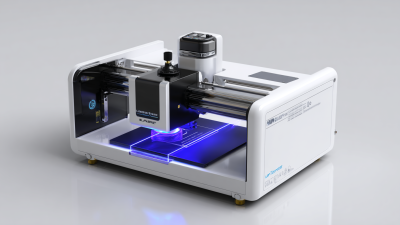

Recent advancements in laser cutting processes, such as the innovative application of laser technology in silicon carbide (SiC) semiconductor wafer manufacturing, illustrate the technology's capability to deliver exceptional performance. SiC, recognized as a third-generation semiconductor material, showcases superior physical and chemical properties, further emphasizing the critical role of precision techniques in the evolving landscape of electric vehicles and electronic components. In light of these developments, businesses looking to optimize their global supply chains should consider investing in state-of-the-art laser cutting services to ensure precision and elevate their product quality amidst escalating market demands.

| Criteria | Description | Importance (1-5) | Weight (%) |

|---|---|---|---|

| Precision | Accuracy of cuts and tolerances achieved | 5 | 30% |

| Material Compatibility | Types of materials that can be processed | 4 | 25% |

| Lead Time | Time taken to complete orders | 4 | 20% |

| Quality Control | Processes in place to ensure quality | 5 | 15% |

| Cost Efficiency | Affordability of services provided | 3 | 10% |

In today's competitive market, cost efficiency is paramount for businesses looking to streamline their global supply chains. Laser cutting services stand out as a transformative solution for reducing production expenses. According to a report by MarketsandMarkets, the global laser cutting machine market is projected to reach $5.7 billion by 2026, showcasing the growing demand for this technology. Laser cutting minimizes material waste, allowing for precise cuts that optimize material utilization—ultimately reducing costs associated with excess scraps.

Tips for cost-effective laser cutting include selecting the right materials and understanding the capabilities of the cutting machine. By opting for more efficient materials, businesses can lower the overall cost while maintaining high-quality output. Additionally, having a clear design and optimizing parts layout can lead to further material savings.

Furthermore, the automation of laser cutting processes contributes to lower labor costs. A study from Deloitte states that automation can reduce operational expenses by as much as 20-30%. Investing in laser cutting technology not only enhances production efficiency but also provides substantial savings over traditional manufacturing methods. Embrace these innovations, and your supply chain will not only be more cost-effective but also robust and agile in meeting market demands.

In today's competitive landscape, the role of laser cutting in manufacturing is critical to accelerating time-to-market for products. This advanced technology, a significant invention of the 20th century, has evolved dramatically over the past 60 years, expanding its applications particularly in high-end manufacturing sectors. In a global supply chain context, laser cutting services offer precision and efficiency, enabling companies to quickly turn designs into tangible products. This capability is vital for businesses aiming to meet the ever-increasing demands of consumers and market dynamics.

Laser cutting's versatility allows for intricate designs and complex shapes that were once difficult to achieve with traditional manufacturing methods. This not only shortens lead times but also enhances the quality and consistency of the products. Companies leveraging laser cutting technology can respond to market changes swiftly, ensuring their products reach the shelves faster than ever. As a cornerstone of modern manufacturing, laser cutting not only streamlines production but also empowers businesses to innovate and stay ahead of the competition.

In recent years, laser cutting services have gained significant attention for their sustainability benefits in manufacturing processes. According to a report by MarketsandMarkets, the global laser cutting market is expected to grow to $5.8 billion by 2025, largely driven by the rising demand for eco-friendly production methods. Unlike traditional cutting techniques, laser cutting produces minimal waste, as it is highly precise, leading to better material utilization. This efficiency not only reduces the overall consumption of raw materials but also lowers the energy required for production.

Moreover, the eco-friendly aspects of laser cutting extend to the types of materials it can handle. Many laser cutting services offer the capability to work with recycled materials, thus promoting circular economy practices. A study by the American Society for Metals highlighted that implementing laser cutting technologies can reduce emissions by up to 50% compared to conventional methods. As companies increasingly prioritize sustainability in their supply chains, incorporating laser cutting services not only aligns with environmental goals but also enhances brand reputation in socially conscious markets.

© 2025 Messer Cutting Systems, Inc.