© 2025 Messer Cutting Systems, Inc.

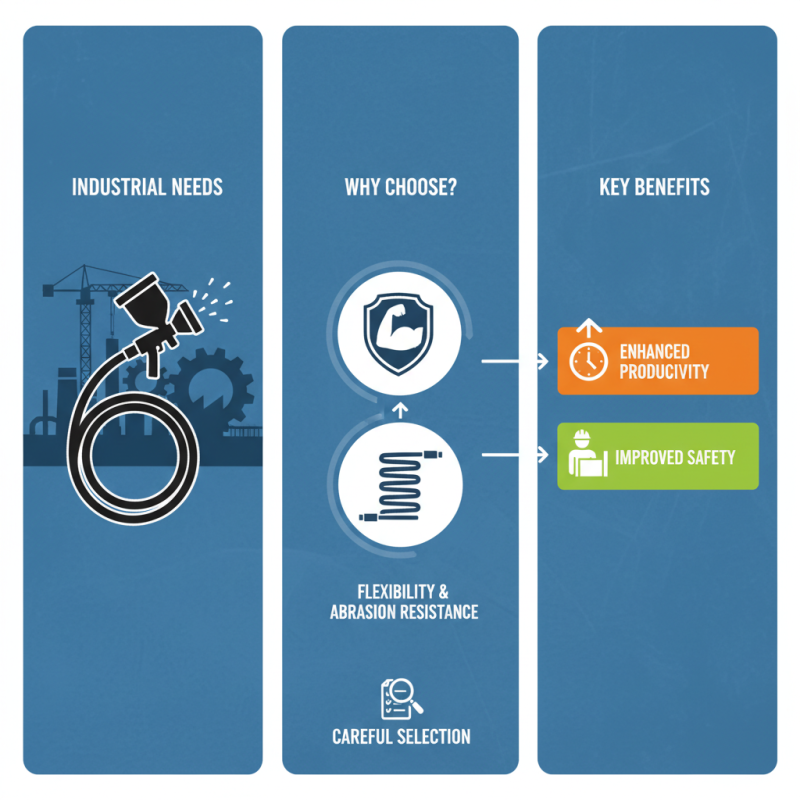

In the industrial sector, choosing the right equipment is crucial. Experts agree that the Sandblast rubber hose plays a vital role in various applications. John Doe, an industry specialist, states, "A reliable sandblast rubber hose can enhance productivity and safety." His observation highlights the importance of selecting quality hoses.

The Sandblast rubber hose is designed for tough conditions. It can handle high pressure and abrasive materials. Many industries, like construction and manufacturing, rely on these hoses for efficient performance. However, not all hoses are created equal. Some may not withstand the rigors of sandblasting.

Choosing a sandblast rubber hose requires careful consideration. Look for durability and flexibility. The right choice can improve job efficiency. Yet, it is essential to assess your specific needs. This decision should not be rushed. Careful evaluation leads to better outcomes in industrial applications.

Sandblast rubber hoses are essential in industrial applications. They are designed for heavy-duty use. The durability of these hoses makes them ideal for various tasks. They withstand high pressure and abrasive materials. This is crucial in environments where safety is a priority. Operators can rely on these hoses to perform effectively.

In industries like construction and manufacturing, efficiency is key. Sandblast rubber hoses allow for continuous operation. They can handle different types of media, including sand and grit. This versatility reduces downtime significantly. However, proper maintenance is necessary. Neglecting this can lead to premature wear or failure.

The flexibility of sandblast hoses enhances usability. They are easier to maneuver in tight spaces. Yet, they may require a learning curve for new users. Training ensures safe and effective handling. Ultimately, investing in high-quality hoses pays off. The overall productivity can increase with the right tools in hand.

When it comes to industrial applications, the choice of hose can significantly impact efficiency. Sandblast rubber hoses are specifically designed for optimal performance in abrasive environments. These hoses offer excellent resistance to wear and tear. They can withstand high pressures, making them ideal for sandblasting tasks.

One notable feature is flexibility. This allows for easy maneuverability during use. Additionally, the hoses are constructed to be lightweight, reducing user fatigue. Another advantage is the heat resistance of sandblast rubber hoses. They perform well in high-temperature scenarios often encountered in industrial settings.

**Tips:** Always inspect your hose for any cracks or damages before use. Keep an extra hose in stock for emergencies. Using the right attachments can enhance performance further. Choosing the appropriate size is essential; a snug fit reduces leaks.

| Feature | Description | Benefits |

|---|---|---|

| Durability | Made from high-quality rubber compounds to withstand harsh environments. | Longer service life and reduced costs on replacements. |

| Flexibility | Highly flexible, retains shape even under extreme conditions. | Ease of handling and installation in tight spaces. |

| Abrasion Resistance | Designed to resist wear from abrasive materials. | Enhances performance and minimizes downtime. |

| Temperature Range | Operates effectively in a wide temperature spectrum. | Suitable for various applications in diverse conditions. |

| Pressure Rating | Built to withstand high pressure during operation. | Increased safety and efficiency in industrial applications. |

When it comes to industrial applications, selecting the right hose type is crucial. Sandblast rubber hoses are specifically designed for abrasive materials. They excel in handling sand, grit, and other coarse particles. Compared to conventional hoses, they offer superior durability and resistance. This is significant in harsh environments where wear and tear are common.

Other hose types, like PVC or standard rubber hoses, may not withstand such abrasive conditions. PVC hoses can crack or become brittle over time. Regular rubber hoses lack the reinforced structure needed for sandblast applications, making them less reliable. However, sandblast rubber hoses can be heavier and may require more effort to handle. This can pose challenges for operators who need flexibility without compromising strength.

It's vital to assess the specific needs of your operation. Consider factors such as pressure requirements and the type of materials being transported. A sandblast hose might be overkill for lighter materials, which could lead to unnecessary costs. Finding the right balance is essential to optimize performance.

To extend the life of a sandblast rubber hose, regular maintenance is essential. Inspect the hose frequently for cracks or wear. Look for any signs of damage, especially near the fittings. These areas often bear the most stress during use. A small tear can quickly lead to bigger problems. Addressing minor issues early can prevent costly replacements later.

Keep the hose clean and free of abrasive materials. After each use, wipe it down thoroughly. Sand and grit can wear down the rubber over time. Store the hose in a cool, dry place, away from direct sunlight. Excessive heat or UV rays can degrade its material.

While it can be tempting to use the hose continuously, giving it breaks is crucial. Overuse can stress the material and affect its performance.

If the hose becomes stiff or loses flexibility, it might be time to reconsider its usage. Regularly check the fittings as well. Loose connections can lead to leaks and inefficiencies. Remember, even the most durable hoses need care and attention. Neglecting maintenance can lead to premature failure. A little effort goes a long way in keeping your hose functional and safe.

Sandblast rubber hoses play a critical role in various industries. They are commonly used for sandblasting, which involves cleaning and surface preparation. This process is vital in industries like manufacturing, construction, and automotive. Sandblast hoses are designed to withstand high pressure and abrasive materials.

In the construction sector, these hoses efficiently remove paint and rust from metal structures. They also prepare surfaces for coatings and finishes. In automotive repair shops, professionals use them to clean parts effectively. The flexibility of sandblast hoses allows easy maneuvering in tight spaces, making tasks simpler. However, choosing the right hose can be challenging.

Some might overlook proper maintenance. This can lead to premature wear or failure. Regular inspections are necessary to ensure performance and safety. The abrasive materials can wear down the hose over time, affecting its lifespan. Understanding the signs of wear can help prevent costly replacements.

© 2025 Messer Cutting Systems, Inc.