© 2025 Messer Cutting Systems, Inc.

In the evolving landscape of metalworking, choosing the right tools is crucial. A "Plasma Cutter" stands out for its precision and efficiency. John Smith, a renowned expert in metal fabrication, once said, "Plasma cutting offers versatility unmatched by traditional methods." This highlights the growing preference for Plasma Cutters.

Unlike other cutting tools, Plasma Cutters use ionized gas to create a high-temperature arc. This process allows for cutting through various metals with ease. Users appreciate the clean edges and minimal material waste. However, they can be challenging to master. Some may struggle to achieve consistent results, especially beginners.

Metalworkers must weigh the pros and cons of adopting a Plasma Cutter. While it can speed up projects significantly, practice is essential. Understanding the settings and techniques is crucial for optimal performance. Reflecting on these challenges may offer insights into the potential of this powerful tool in metalworking.

Plasma cutters are revolutionizing

metalworking. Their speed and precision make them a popular choice.

This tool uses high-temperature plasma to cut through various metals. From steel

to aluminum, plasma cutters handle it all. They allow for intricate designs that other methods struggle with.

Smooth edges result in less finishing work.

The versatility is impressive. A plasma cutter can adapt to different thicknesses easily.

Adjusting settings is often straightforward. However, operating a plasma cutter requires

skill and practice.

Errors can lead to wasted materials. Learning the right technique is crucial for achieving quality cuts.

New users might find the first attempts challenging.

Despite the benefits, one should consider safety measures.

Protective gear is a must. Plasma cutting generates intense heat and light, which can be harmful.

Proper ventilation is also necessary to avoid inhaling fumes. Understanding the equipment and potential hazards is vital.

Balancing speed and safety can be tricky.

Plasma cutting technology has revolutionized the metalworking industry. It uses an ionized gas to cut through various metals. This process is efficient and precise, making it ideal for professionals and hobbyists alike. The speed of a plasma cutter is impressive. It can slice through thick materials quickly, enhancing productivity.

The versatility of plasma cutting is notable. It works well on steel, aluminum, and even copper. This adaptability makes it a valuable tool in metal fabrication. Many users appreciate how easily plasma cutters can adjust to different thicknesses. However, it can be challenging for beginners. They may struggle with the settings and techniques involved.

Understanding the nature of plasma cutting is vital. It may create rough edges requiring additional finishing work. Those new to the trade should be prepared for a learning curve. Each project can offer unique challenges. Embracing these challenges is part of the journey.

Plasma cutters are a popular choice in metalworking. They excel in speed and precision compared to traditional methods. Oxy-fuel cutting is slower and often leaves rough edges. Band saws can be limited by material thickness. Plasma cutters offer versatility for various metals, including stainless steel and aluminum.

When choosing a plasma cutter, consider your specific needs. If you often cut thick materials, a high-powered plasma cutter might be worth the investment. However, for thinner sheets, you may find that lower power options work just as well.

**Tips:** Always wear appropriate safety gear when cutting metal. Protective eyewear is essential to shield yourself from sparks. Also, keep your work area clean to prevent accidents.

It's essential to practice operating a plasma cutter. Understand its settings and techniques. Any mistakes can lead to waste or subpar results. Learning from these experiences is crucial for improving your skills.

When considering a plasma cutter, it’s essential to focus on key features that will enhance your metalworking experience. A reliable plasma cutter should have a robust power output. This directly impacts cutting speed and efficiency. Look for an adjustable amperage range. It allows you to customize power based on the thickness of the metal being cut.

Another crucial feature is the design of the torch. A comfortable, ergonomic torch can significantly improve precision. A lightweight torch reduces fatigue during extended use.

Tip: Consider the portability of the plasma cutter. If you need to move it often, a lighter model is beneficial.

Additionally, check for ease of consumable replacement. Regular maintenance is necessary for optimal performance. A cutter that allows quick changes can save valuable time.

Tip: Always keep spare consumables on hand. This prevents downtime during a project.

Incorporating these features in your selection process will lead to a more effective plasma cutting experience. While you may find options with advanced technology, don't overlook basic performance reviews. Sometimes the best option is simpler.

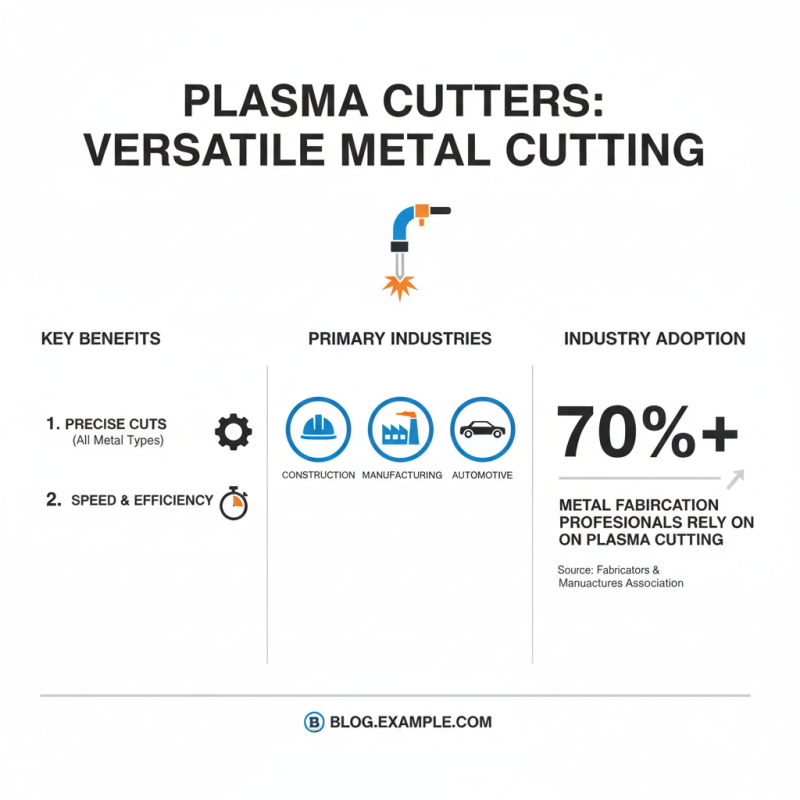

Plasma cutters are versatile tools used across various industries. They provide precise cuts on different types of metals, making them invaluable in construction, manufacturing, and automotive sectors. According to a report by the Fabricators and Manufacturers Association, over 70% of metal fabrication professionals rely on plasma cutting for its speed and efficiency.

In construction, plasma cutters are used to cut steel beams and plates. This allows for faster assembly and reduces labor costs. In the automotive industry, they help in shaping metal parts with intricate designs. Reports indicate that manufacturers using plasma cutters can increase production rates by as much as 50%. However, inconsistency in cut quality can sometimes lead to rework, highlighting areas for improvement.

Moreover, the energy sector often employs plasma cutting for pipeline repairs and maintenance. Crafting precise cuts saves both time and resources. Yet, despite the benefits, some operators may overlook safety protocols. This can lead to accidents or equipment damage. Investing in training and proper safety measures is crucial. The need for continuous education and awareness remains in the industry.

© 2025 Messer Cutting Systems, Inc.