© 2025 Messer Cutting Systems, Inc.

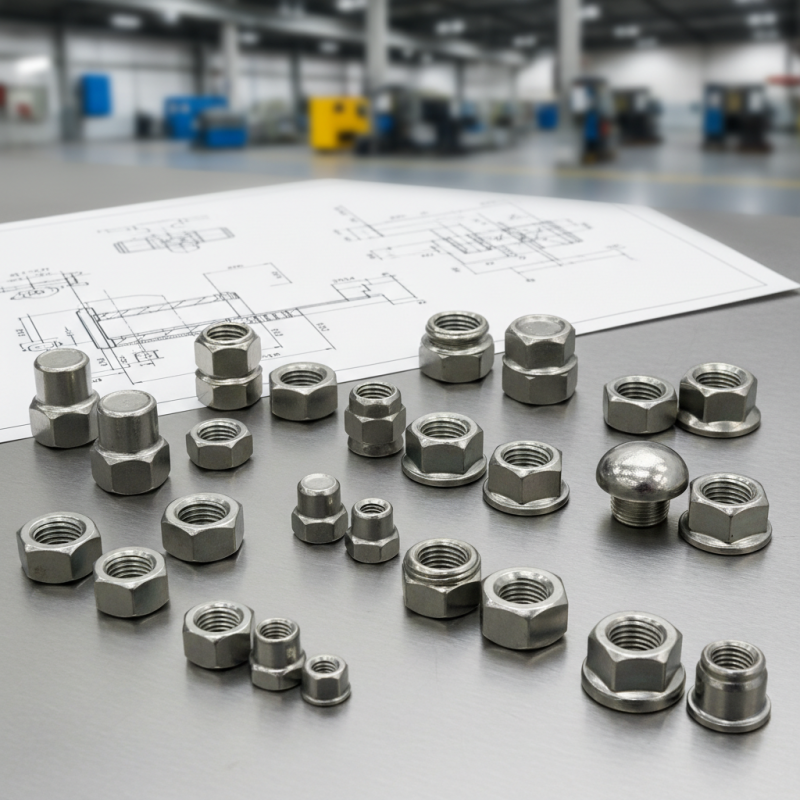

In today's fast-paced industrial landscape, the choice of hardware can significantly impact project outcomes. "Stainless Hex Nuts" are critical components in various applications, from construction to automotive. According to a report by Market Research Future, the global stainless steel fasteners market is projected to reach $27 billion by 2025, indicating a robust demand for these components.

John Smith, a renowned expert in fastener technology, emphasizes, "Selecting the right stainless hex nut can make or break your project's integrity." This insight highlights the importance of understanding the different types of stainless hex nuts available. Factors such as material grade, environmental conditions, and load requirements must be considered in selection.

While many may opt for standard options, not all stainless hex nuts are created equal. There are potential pitfalls in choosing based solely on price or appearance. A thorough assessment is essential. With the right knowledge and tools, industries can enhance their applications, ensuring safety and reliability.

When looking for the best stainless hex nuts, it's essential to consider the application. Different projects require different types of nuts. Some might need strength, while others need resistance to corrosion. Stainless steel nuts are versatile, offering durability and reliability across various environments.

For outdoor applications, grade 316 stainless steel nuts excel. They resist rust and corrosion from moisture and salt exposure. On the other hand, grade 304 nuts are often suitable for indoor tasks. They offer good strength and decent corrosion resistance for a lower cost. However, in humid environments, even grade 304 can falter over time.

It's easy to overlook the importance of proper selection. Many users may rush in without understanding specific requirements. This can lead to poor performance or premature failure. Matching the hex nut to the application is crucial. Review the needs carefully before making a choice; sometimes, the best option isn't the most obvious one.

When selecting stainless hex nuts, understanding the various grades of stainless steel is crucial. Stainless steel grades like 304 and 316 offer different properties. For example, grade 304, often referred to as "18/8," consists of 18% chromium and 8% nickel. This makes it resistant to rust and corrosion. It is widely used in architectural and food processing applications. However, in environments with high chloride content, grade 304 may not perform well. Here, grade 316 shines due to its molybdenum addition, granting enhanced corrosion resistance.

Reports indicate that stainless steel usage is increasing in construction and automotive sectors. According to a recent industry study, about 50% of stainless steel is used for these applications. Yet, not all manufacturers provide detailed information about their materials. This lack of transparency can lead to issues when specific properties are required, such as tensile strength or impact resistance. Inadequate information may lead engineers to overlook the importance of choosing the right grade for their projects. Each grade has its limitations and specific applications, making informed choices essential.

Stainless hex nuts are vital in many industries. They offer strength and resistance to corrosion. This makes them suitable for applications in construction, automotive, and aerospace sectors. According to a recent market report, the demand for stainless steel fasteners is expected to grow by 5.5% annually through 2026. This statistic highlights their importance.

In construction, stainless hex nuts hold together structural components. They withstand tough weather conditions. A study revealed that around 30% of construction projects use stainless steel hardware for longevity. Automotive industries use these nuts in engines and frames for reliability and safety. Another report indicated that 20% of automotive manufacturers prefer stainless hex nuts for their durability.

A persistent challenge is ensuring proper torque levels during assembly. Undertorqued nuts can lead to joint failures. Over-torqued nuts can cause stripping and breakage. This area deserves more attention. Maintaining precise torque is crucial for performance. Consistent data collection in this aspect is still a work in progress. Improvements can lead to safer and more efficient applications across industries.

When it comes to hex nuts, different designs serve distinct purposes. The most common types include standard, serrated, and winged hex nuts. Standard hex nuts are plain and versatile. They work well in most applications, offering solid grip and torque. Serrated hex nuts have notches on one side to prevent loosening. This design is excellent for vibration-prone environments, where standard nuts might fail.

Winged hex nuts allow for easy manual tightening. Their unique shape provides a good grip. However, they may not suit high-torque applications. Each design has strengths and weaknesses. Standard nuts are universal but may require additional locking mechanisms. Serrated nuts are reliable but can wear down over time. Consider the specific needs of your project carefully.

In real-world applications, the choice may not always be straightforward. Environmental factors can affect performance as well. For example, exposure to moisture can lead to corrosion. This is an essential consideration for outdoor projects. Ultimately, the ideal hex nut is one that matches the requirements. Do you have the right balance of grip, strength, and corrosion resistance? It's a question worth pondering.

| Type | Material | Corrosion Resistance | Common Applications | Tensile Strength (MPa) |

|---|---|---|---|---|

| Standard Hex Nuts | 304 Stainless Steel | Good | General Construction | 515 |

| Heavy Hex Nuts | 316 Stainless Steel | Excellent | Marine Applications | 620 |

| Lock Nuts | A2 Stainless Steel | Good | Vibration Prone Areas | 500 |

| Flanged Hex Nuts | A4 Stainless Steel | Excellent | High Load Applications | 600 |

When selecting stainless hex nuts for a project, several factors deserve careful consideration. Material quality is critical. Rust resistance is essential for outdoor applications. Different grades of stainless steel offer varied levels of corrosion resistance. Choosing the appropriate grade affects durability, especially in harsh environments. Yet, many overlook this vital detail.

Environmental conditions play a significant role. Nuts exposed to saltwater or chemicals require higher resistance levels. Some may choose standard nuts, only to find them corroding in a few months. Always assess the nature of the application. Additionally, the required strength and load capacity are also pivotal.

Another vital aspect is compatibility with other fasteners. Mismatched nuts and bolts can lead to failure. Standardization often leads to better performance, but many skip this step. Lastly, consider the assembly method. Ease of installation is crucial, yet sometimes neglected. Weighing these elements can lead to more successful projects, avoiding costly mistakes.

© 2025 Messer Cutting Systems, Inc.