© 2025 Messer Cutting Systems, Inc.

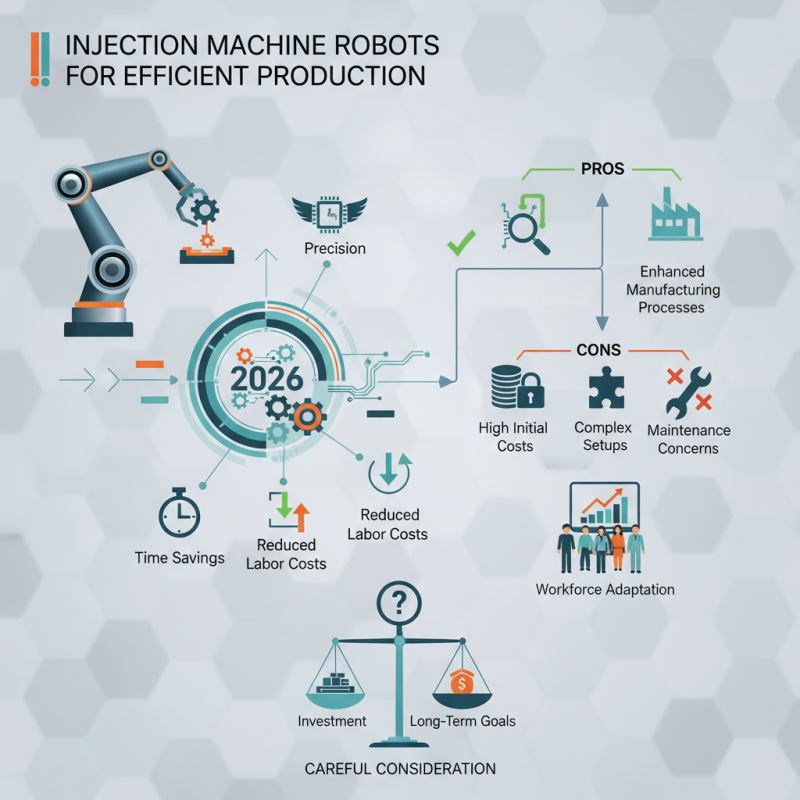

In the quest for efficient production, the role of the Injection Machine Robot has become increasingly vital. In 2026, this technology promises to further enhance manufacturing processes across various industries. These robots automate tasks, ensuring precision and speed, which lead to significant time savings and reduced labor costs.

While the advantages are clear, the integration of Injection Machine Robots is not without challenges. Many companies struggle with the high initial costs and complex setups. Maintenance concerns and the need for skilled operators also arise. As automation becomes more common, the workforce must adapt to these changes.

Investing in the right Injection Machine Robot can redefine production efficiency. However, careful consideration is necessary. Understanding the specific needs of a manufacturing line is crucial. Decision-makers must weigh the pros and cons, ensuring that this technology aligns with their long-term goals.

Injection machine robots are transforming modern manufacturing. These automated systems enhance production efficiency and precision. They are crucial in industries like automotive and consumer goods. Advanced robotics streamline processes by reducing human error and increasing output. Manufacturers are increasingly relying on these machines for better consistency.

Despite their advantages, challenges remain. Integrating robotic systems requires careful planning. There can be a learning curve for operators. Machines need regular maintenance to function at their best. Performing checks can be time-consuming. However, addressing these details can lead to improved performance.

The innovation in injection machine robots opens up new possibilities. They can adapt to different materials and designs. Companies must remain vigilant and assess the effectiveness of these robots. Balancing automation with manual oversight is essential. This approach encourages continuous improvement and optimizes productivity.

When selecting the best injection machine robots, several key features deserve attention. Speed and precision are vital. Reports indicate that the top machines can produce up to 600 parts per hour, significantly boosting productivity. Ensuring that the robot can operate within tight tolerances is crucial. A misaligned part can lead to defects and increased waste, which isn't sustainable.

Another important consideration is flexibility. Modern production lines require robots that can handle various shapes and sizes. According to industry data, machines with adaptable programming can reduce setup time by as much as 30%. This responsiveness can be a game-changer for manufacturers. Additionally, integrating advanced sensors for real-time monitoring can enhance operational efficiency.

Cost of ownership should also be evaluated. Comprehensive studies show that maintenance costs can account for up to 15% of the total operating expenses. While it’s easy to focus on upfront costs, long-term expenses matter more. Some robots may be cheaper initially but require frequent repairs, ultimately increasing costs. Reflecting on these aspects can lead to more informed decisions.

In the world of manufacturing, injection machine robots are crucial. They enhance production efficiency and accuracy. The year 2026 brings innovative options for businesses. Selecting the right robot can be overwhelming. Here’s a closer look at some of the top contenders in the market.

One notable development is the focus on flexibility. Many robots are designed to handle various materials. This adaptability can lead to cost savings. However, not every robot excels in every application. Companies must assess their specific needs. Moreover, integration with existing systems can pose challenges. Operators must often adapt to new technology, leading to potential downtime.

Another trend is the rise of smart features. Advanced sensors and AI capabilities allow for real-time monitoring. This improves the overall efficiency of the production line. Yet, relying solely on technology may overlook the human element. Training is essential for staff to harness these advancements effectively. Without proper training, machines may not perform as expected. It's a delicate balance between automation and human oversight.

| Model | Payload Capacity (kg) | Production Speed (units/hour) | Precision (mm) | Energy Efficiency (%) |

|---|---|---|---|---|

| Model A | 150 | 200 | 0.05 | 90 |

| Model B | 120 | 180 | 0.07 | 85 |

| Model C | 200 | 220 | 0.04 | 92 |

| Model D | 160 | 210 | 0.06 | 88 |

| Model E | 140 | 195 | 0.05 | 87 |

Injection machine robots are transforming modern production lines. These robots enhance operational efficiency and significantly reduce costs. According to a study by the International Federation of Robotics, automation in manufacturing can boost productivity by 30% or more. Robots minimize human error, ensuring a consistent product quality.

One key benefit is speed. Injection machine robots operate rapidly, executing processes in seconds rather than minutes. This speed can lead to a marked increase in output without sacrificing quality. Moreover, they can work continuously, enabling production to run around the clock.

Tips: Regular maintenance can prolong the life of injection robots. Training staff on new technologies is vital. A well-informed team enhances productivity even further. It’s important to assess which tasks should remain manual. Not all operations benefit from full automation. Balancing human labor with robotic efficiency can bring the best results.

The future of injection machine robotics is rapidly evolving. Increased automation leads to higher efficiency in production. Companies invest heavily in advanced technologies. However, the integration can be challenging. Workers need training to adapt to new systems. Productivity may not show immediate gains.

Robots can reduce production costs, but some issues arise. Maintenance can become a burden without proper planning. Software updates may cause temporary downtime. Additionally, the need for flexibility in operations persists. Customization options are often limited with standard machines.

Sustainability is becoming crucial in this sector. More eco-friendly practices are being explored. Innovations in materials and energy use are emerging. Yet, the transition to greener technologies faces obstacles. Not all facilities can afford the upgrade. Balancing cost and efficiency continues to be a puzzle for many manufacturers.

© 2025 Messer Cutting Systems, Inc.