© 2025 Messer Cutting Systems, Inc.

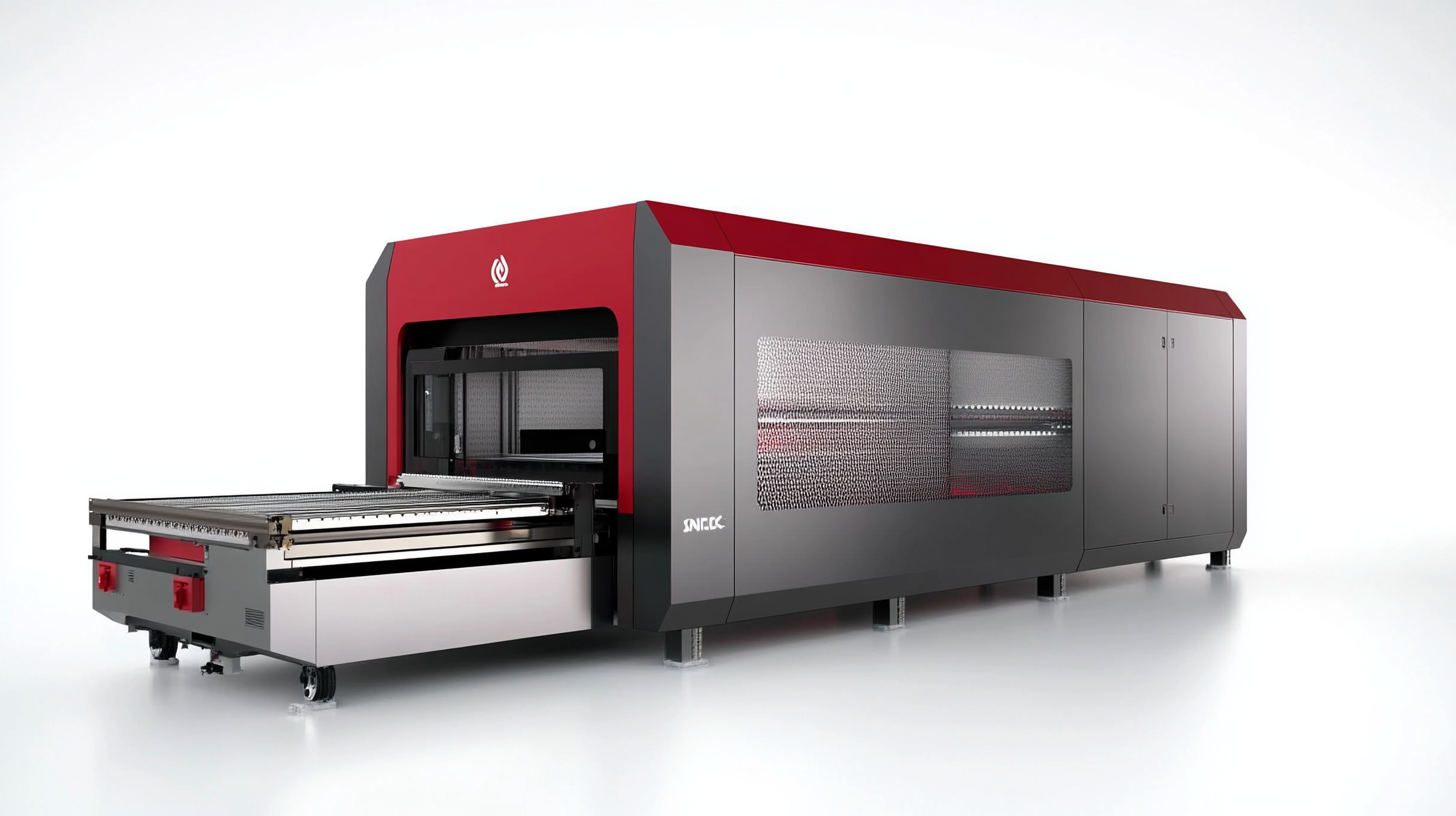

In the rapidly evolving landscape of modern manufacturing, precision and efficiency go hand in hand. One of the most transformative technologies leading this charge is the Fiber Laser Cutting Machine. This advanced tool not only enhances cutting accuracy but also significantly reduces operational costs, making it an indispensable asset for manufacturers striving to optimize their production processes. With its unique ability to cut through a wide range of materials, from metals to composites, the Fiber Laser Cutting Machine is revolutionizing how industries approach design and fabrication.

As competition intensifies and market demands shift, manufacturers are increasingly recognizing the importance of adopting cutting-edge technologies like fiber laser cutting. These machines are not just enhancing traditional methods; they are redefining what is possible in terms of speed, precision, and versatility. In this article, we will explore the key benefits of Fiber Laser Cutting Machines, their applications in various industries, and how they are shaping the future of manufacturing in ways we could have hardly imagined a decade ago.

The evolution of fiber laser cutting technology has significantly transformed the landscape of modern manufacturing. Unlike traditional cutting methods, fiber lasers utilize advanced technology to deliver highly focused beams of light, enabling precise cuts in a variety of materials. According to a report by MarketsandMarkets, the global fiber laser market is expected to reach $5.72 billion by 2025, growing at a CAGR of 10.3% from 2020. This growth reflects the increasing adoption of laser cutting systems across multiple industries such as automotive, aerospace, and electronics, where precision and efficiency are paramount. One major advantage of fiber laser cutting is its ability to cut through reflective materials, such as copper and aluminum, which are often challenging for CO2 lasers. A study published by ResearchAndMarkets highlights that fiber lasers can achieve cutting speeds up to three times faster than their CO2 counterparts while offering lower operational costs. Additionally, the maintenance requirements for fiber laser machines are notably reduced, further enhancing their appeal in high-volume production environments. As manufacturers continue to seek innovative solutions to improve productivity, the integration of automation in fiber laser cutting systems is becoming increasingly prevalent. Automated systems can operate continuously, reducing labor costs and minimizing downtime. The Global Laser Cutting Machine Market Analysis indicates that automated fiber laser cutting technologies are projected to account for a significant share of the market, underscoring the technology's role in driving operational efficiency and precision in modern manufacturing.

Advanced fiber laser cutting machines are transforming the landscape of modern manufacturing by offering unparalleled precision and efficiency. These machines use high-powered laser beams to cut through a variety of materials, enabling manufacturers to achieve complex designs and intricate shapes that traditional cutting methods struggle with. This advanced technology not only improves the quality of cuts but also enhances the overall productivity of manufacturing processes, making it an essential investment for industries looking to stay competitive.

One of the key advantages of advanced fiber laser cutting machines is their speed. Compared to conventional cutting methods, fiber lasers can operate at significantly higher speeds, drastically reducing production times. This efficiency is particularly beneficial in high-demand sectors, such as automotive and electronics, where rapid turnaround is crucial. Additionally, fiber lasers maintain a high degree of accuracy, resulting in minimal waste and cost savings in materials.

Another significant benefit is the versatility of fiber laser cutting machines. They are capable of processing a wide range of materials, including metals, plastics, and composites. This adaptability allows manufacturers to diversify their product offerings without the need for extensive retooling or new equipment. Furthermore, advancements in technology have led to improved cutting quality, even in thick materials, making fiber lasers a preferred choice for heavy industrial applications. As the demand for high-quality manufacturing continues to grow, the role of advanced fiber laser cutting machines will undoubtedly become even more prominent.

Advanced fiber laser cutting machines are transforming the landscape of modern manufacturing, offering unparalleled precision and efficiency across various industries. According to a market report by Grand View Research, the global fiber laser market size is expected to reach USD 5.8 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.8% from 2019 to 2025. This growth is largely driven by the increasing demand for accuracy and flexibility in cutting applications, which fiber lasers are uniquely equipped to meet.

In the automotive industry, fiber laser cutting machines are redefining production standards. They enable manufacturers to cut complex shapes in high-strength materials with remarkable speed and precision. For instance, the cutting speed of fiber lasers can reach up to 30 meters per minute, significantly reducing production times. According to a study by the International Journal of Advanced Manufacturing Technology, the implementation of laser cutting technology has led to an average decrease in waste material by 15%, optimizing resource utilization.

Beyond automotive, fiber laser cutting is making waves in the aerospace sector. The ability to work with lightweight materials, such as titanium and aluminum alloys, allows for the creation of intricate components that meet strict regulatory standards. Reports indicate that the aerospace industry is poised to expand by 5% annually, with laser cutting technology playing a critical role in meeting the high demand for precision-engineered parts. As manufacturers adopt these advanced techniques, we can expect to see improvements in product quality and overall efficiency across numerous applications.

In the realm of modern manufacturing, precision is paramount, and fiber laser cutting technology stands at the forefront, offering remarkable advantages over traditional methods. Traditional cutting techniques, such as mechanical cutting and stamping, often struggle with the complexities of modern materials, leading to inefficiencies and wasted resources. In contrast, fiber lasers provide a high degree of control, allowing for cleaner cuts at faster speeds, which is crucial in industries that demand both accuracy and speed.

The benefits of fiber lasers extend beyond mere cutting precision. Recent developments in laser technology, such as the use of high-power blue diode lasers, illustrate the ongoing innovation in this area. These advancements can significantly impact not only manufacturing but also medical applications like the vaporization of prostate tissue, showcasing the versatility and precision that laser technology offers. Additionally, fiber lasers require less maintenance and have a longer lifespan compared to their traditional counterparts, reducing overall operational costs and making them a more sustainable choice for manufacturers seeking to enhance efficiency.

Furthermore, the integration of fiber laser cutting with automated systems allows for streamlined processes in factories, paving the way for a fully automated production environment. The synergy between fiber lasers and advanced manufacturing technologies, such as 3D printing and artificial intelligence, positions fiber laser cutting as an essential component in the evolution of precision manufacturing. As industries continue to seek innovative solutions, fiber lasers present a compelling case for those looking to transform their manufacturing processes while achieving unparalleled accuracy and reliability.

The landscape of manufacturing is undergoing a profound transformation, driven by advancements in fiber laser cutting technology. According to a report from Research and Markets, the global fiber laser market is expected to reach approximately $5.40 billion by 2025, growing at a CAGR of 10.5%. This growth can be attributed to the remarkable benefits that fiber laser cutting machines offer, including superior speed, precision, and cost-efficiency, making them increasingly essential in sectors ranging from automotive to aerospace.

As industries seek ways to enhance production efficiency, fiber laser technology's adaptability stands out. With its ability to cut through a variety of materials—such as metal, plastic, and wood—at remarkable speeds, this technology is being increasingly integrated into automated manufacturing systems. A study by Grand View Research highlights that the adoption of fiber lasers in automated processes can improve cutting speed by up to 40% and reduce operational costs significantly, thereby reshaping traditional manufacturing processes into more streamlined operations.

Future trends indicate a significant shift towards the integration of smart technologies with fiber laser cutting machines. Industry leaders are increasingly exploring the potential of AI and IoT for predictive maintenance and real-time monitoring. According to a recent study by McKinsey, companies that adopt intelligent manufacturing technologies can realize operational efficiencies of up to 30%, potentially revolutionizing production timelines and supply chain dynamics. As these trends continue to evolve, the fiber laser cutting market is poised to play a pivotal role in the future of modern manufacturing, setting new standards for precision and efficiency.

© 2025 Messer Cutting Systems, Inc.